Topic: [TPV] Irogran A85

TPV (thermoplastic vulcanizate) is in the family of other flexibles like TPE (ninjaflex) and TPU (semiflex). While TPE is much like a wet noodle, and TPU is a little more like a stiff boot lace, TPV is more like a rubberized noodle. I have never extruded anything but ABS until Irogran A85 TPV, so this was as fun as it was aggrivating as there is no discussion on extruding this material.

Extruder:

Mostly stock Filastruder v1.6 #1870 extruding vertically with full barrel header wrap insulation, and a Filawinder. For this material, I have to drill the nozzle out with a 5/64" drill bit.

Drying:

I printed a hotbox that comfortably hold 500g of pellets, placed it on my Hale heatbed at 115c for roughly 5 hours with some dessicates, then stored them overnight for later extrusion. Drying is not an option for this material.

Image of drying PETG

Extrusion:

Temp: 175c

Rate: 37" per minute

Average diameter: 1.68-17.9mm.

Extrusion was a nightmare at first. The filament would leave the nozzle at 2.60(ish)mm, but only inches away would shrink to 1.05mm. This led me to wonder what was wrong: Temperature? Cooling? Nozzle diameter? Moisture?

Well, I can rule out drying since my method has been proven to work as you will see, and I will explain shortly.

I instantly started thinking of cooling, but I was dreading that fix since I dont have enough minutes in the day to design and print new fan adapters. So that was out of the question.

Temps? I played around with settings as low as 173c, nut still had an average 1.53mm diameter, so this led me to nozzle diameter.

Once I drilled the nozzle with a 5/64" bit and cleaned out the metallic shavings and TPV remnants with an overnight acetone soak and a short blast from a compressor, the nozzle was clean as a whisle. I purged any potential debris and used this at my 175c to get my average diameter of 1.73mm.

No matter my temp settings, STB adjustments, or nozzle diameter, I still got random "furred" filament, which acted a little like moisture, but only happened at random even in perfectly consistent filament. Only after poking my head under the nozzle did I find that balls of TPV were accumulating over time around the nozzle's exit which caused friction and dragged still-hot material causing the texture in question. With that said, I highly recommend not using a winder when extruding this specific polymer. I simply let mine drop onto a box about 24" below the nozzle and this yielded a far more consistent texture.

Printer:

Solidoodle 2, E3D Titan, v6, Volcano, .6 nozzle, Lawsy carriages, Claghorn direct Y drive, bed stabilizer

Printing:

217c/60c, glass with hairspray

Speeds had to be slowed way down to 18mm/s for perimeters and retraction was a snail's pace at 5mm/s.

Printing was a problem for me. Of the three working printers I have, one is bowden and the other two are geared (Bulldog XL and E3D Titan). I highly doubt the bulldog would be able to reliably print TPV, so I was stuck with the Titan. The E3D Titan is capable of printing flexibles, but I haven't had much successful testing with TPE and never got around to testing TPU.

The TPV would constantly buckle in the extruder during retraction if I was attempting anything with infill, so I was only able to print a spiral vase with no bottom. And even then, I had voids popping up.

Comparison to available filament:

I have never used TPV filament, and I am fairly sure the only flexibles available are TPE and TPU.

Takeaway and comments:

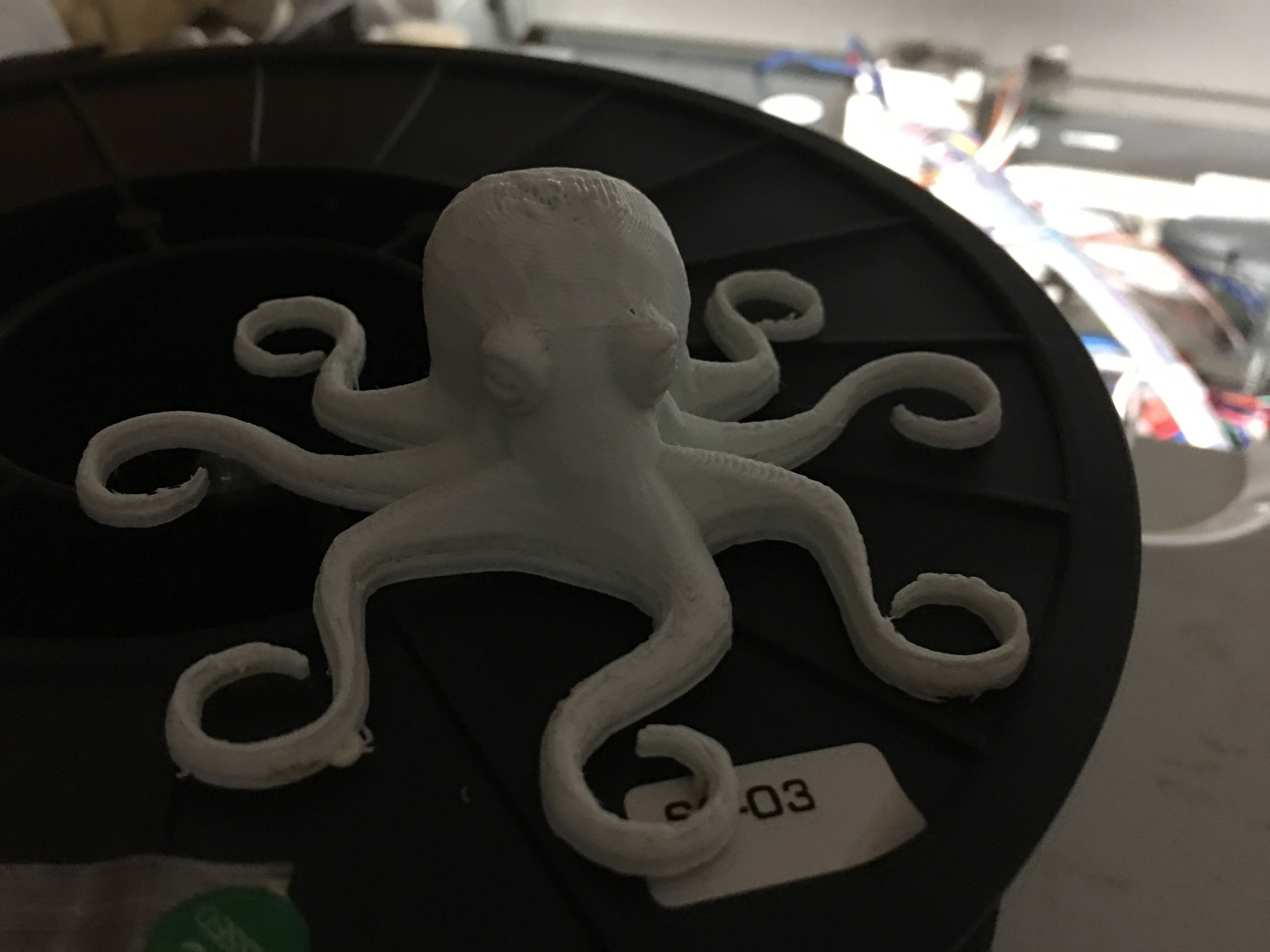

This is not a negative review, nor am I saying it is bad. I am sure with better settings or even a non-geared extruder with some type of flexibles support it would be very reliable on a printing side, and extrusion is best with no winder. Just let it drop to the floor and you will get a much higher quality filament. As a matter of fact, I send an image to a buddy of mine putting together a Spiderman cosplay project and A85 with no colorants, twisted, and knotted up looks a lot like Spiderman's webs. So he will be making backpacks and whatnot with the filament that was too small in diameter to test with printing. I also ordered more so I can really play around with it now that I can reliably extrude it, but printing is the only hurdle. Perhaps someone will get A85 TPV to print consistently before I get one of my other printers up and running.

Multiple SD2s- Bulldog XL, E3D v5/v6/Lite6, Volcano, Hobb Goblin, Titan, .9 motor, Lawsy carriages, direct Y drive, fishing line...the list goes on

Filawinder and Filastruder #1870.....worth every penny!