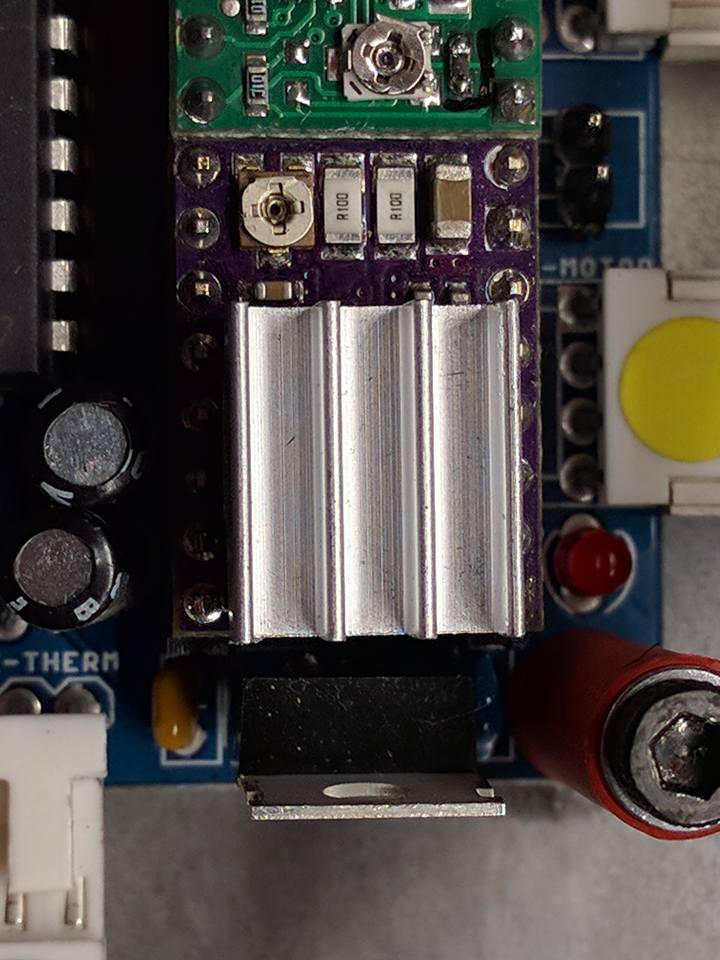

Topic: Pololu DRV8825 for Extruder

I purchased and installed a Pololu DRV8825 onto my Sang board on my SD2. I set the Vref based on this Soliforum post at 0.2. I didn't have to change the steps/mm in Repetier (or more correctly when I changed it was extruding double so I set it back). I know this is a drop-in type replacement for the stock A4988 driver. I left the three jumpers in place. Is mine working at 1/32 or is it still in 1/16 mode? I also seem to be reading that the Vref should be 0.5V.

I read on the replacement parts post that the stock SD2 motor is rated at 1.3A so perhaps 0.6 VRef would be better.... running at 0.2 VRef I've had seemingly fine prints and when printing 0.5mm layer height everything is nearly perfectly smooth. Anyone else have a DRV8825 for their extruder? The impetus was to eliminate Moire pattern...

References

https://www.pololu.com/product/2133

http://www.soliforum.com/topic/2817/ste … ref-chart/

http://www.instructables.com/id/Install … -on-RAMPS/

http://reprap.org/wiki/A4988_vs_DRV8825 … ver_Boards

Edit:

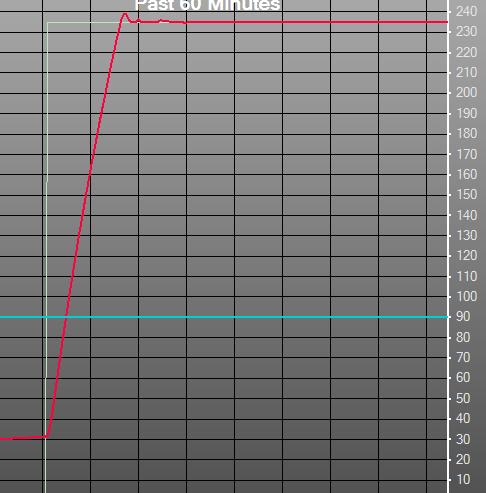

Also read http://cabristor.blogspot.com/2015/02/d … steps.html My power supply is 12V. I'm thinking of trying the fast decay mode... well actually first I will set Vref to 0.5V and try that and then thinking of trying Fast Decay.

- E3D V6 hotend; 30A PSU; Glass bed for ABS or Blue Tape on glass for PLA

- X-axis NEMA 14 press on fan (thing:1871741); Lawsy almost everything else; 3mm Z axis rod (thing:1868824)

- Sang board w/all headers, ATmega1284P w/OptiBoot and Marlin beta firmware; VRef tuned