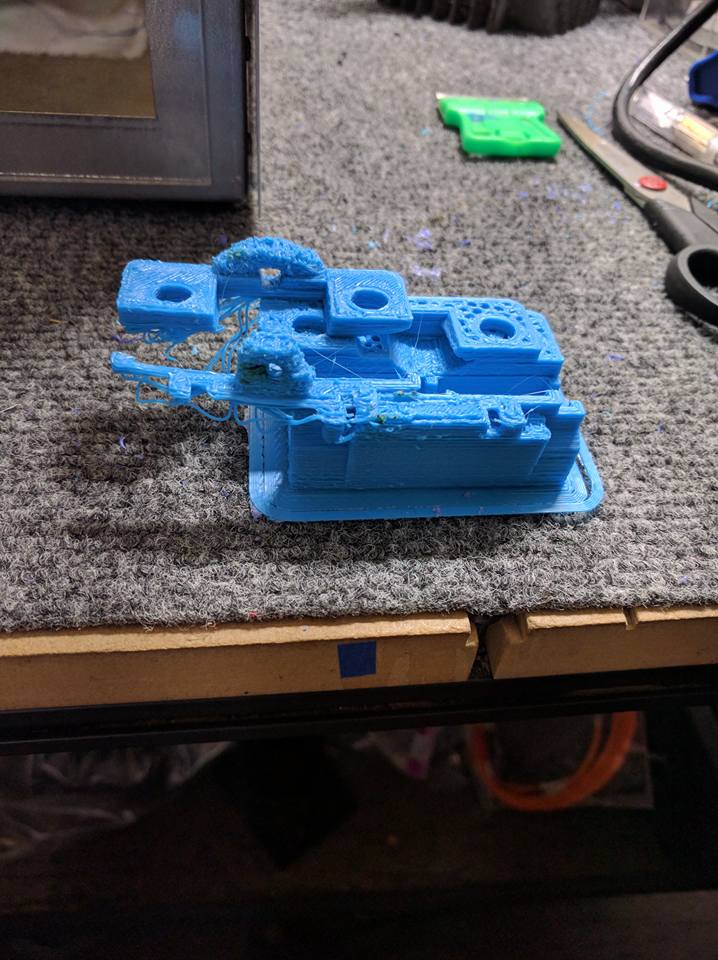

Topic: Bearings Don't Fit ABS Printed Parts

I printed Lawsy's carriages since I'm having all sorts of issues with my prints. The secondhand Solidoodle 2 Pro came with two spools of ABS... my basement is cold and even with the enclosure and the bed at 105C I get warping... I've tuned out most of the other really bad issues... anyways I woke up this morning to one of the carriages looking like this after 8 hours (I tried slowing things down)

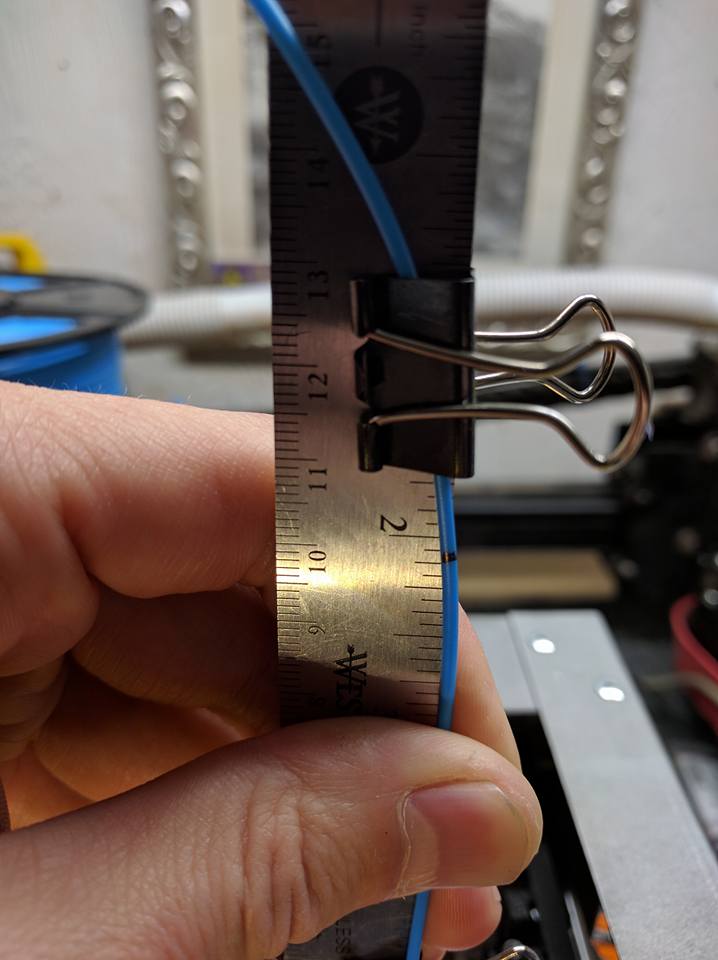

My 8mm linear bearings arrived and don't seem to fit and I wonder if it's because ABS contracts so much? I have a spool of PLA on order and maybe it's more forgiving...

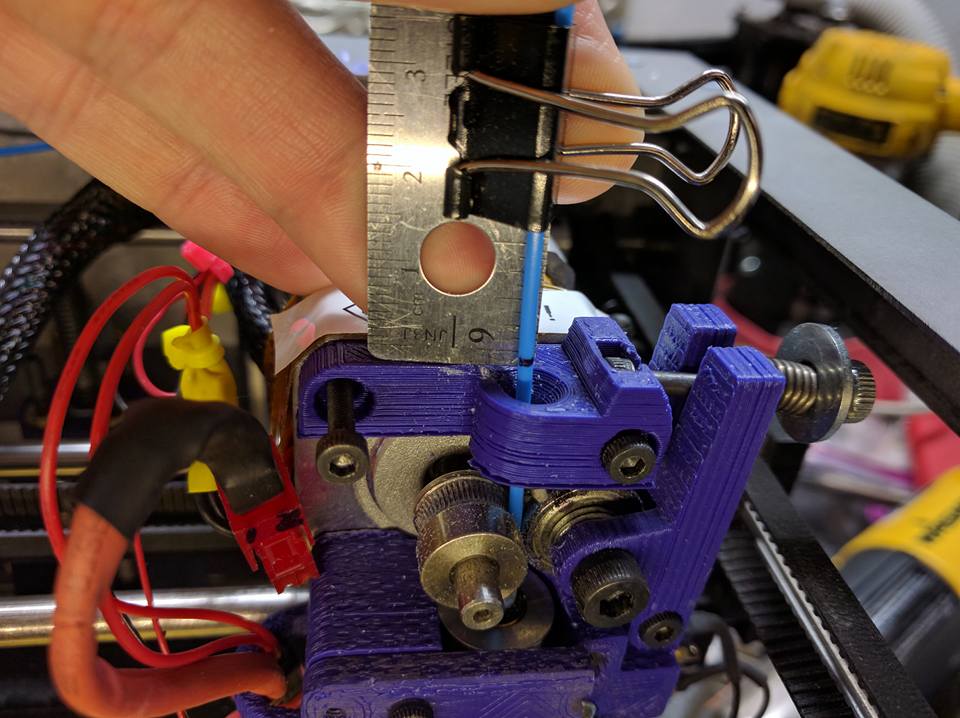

- E3D V6 hotend; 30A PSU; Glass bed for ABS or Blue Tape on glass for PLA

- X-axis NEMA 14 press on fan (thing:1871741); Lawsy almost everything else; 3mm Z axis rod (thing:1868824)

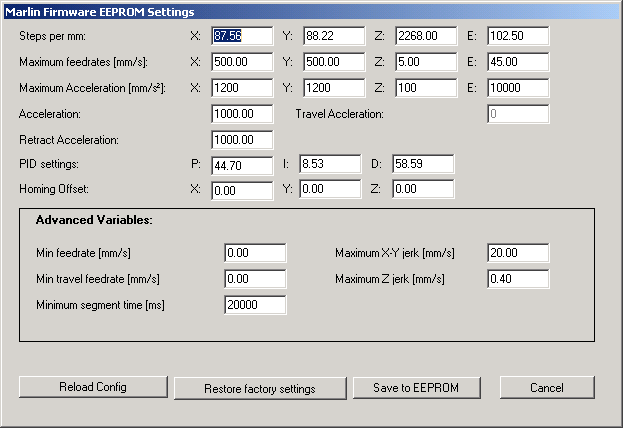

- Sang board w/all headers, ATmega1284P w/OptiBoot and Marlin beta firmware; VRef tuned