Topic: [Copolyester/PETG] - Eastman EASTAR Copolyester 6763 + Powder colorant

Resin: Eastman EASTAR Copolyester 6763 (datasheet: http://www.eastman.com/Literature_Center/M/MBS80.pdf )

Purchased here. Price is $2.72 a pound from this particular seller (they will not sell less than 55lbs per order though), so about the same as ABS pellets in this quantity. Mine had a bit of a leak (the inner plastic bag developed a hole during shipping, and the tape would let some leak out when moving the box), but they include a little more than the stated 55lbs, so even with it losing some pellets in transit (and on the way from my front porch to the garage) I still got at least 55lbs according to my scale.

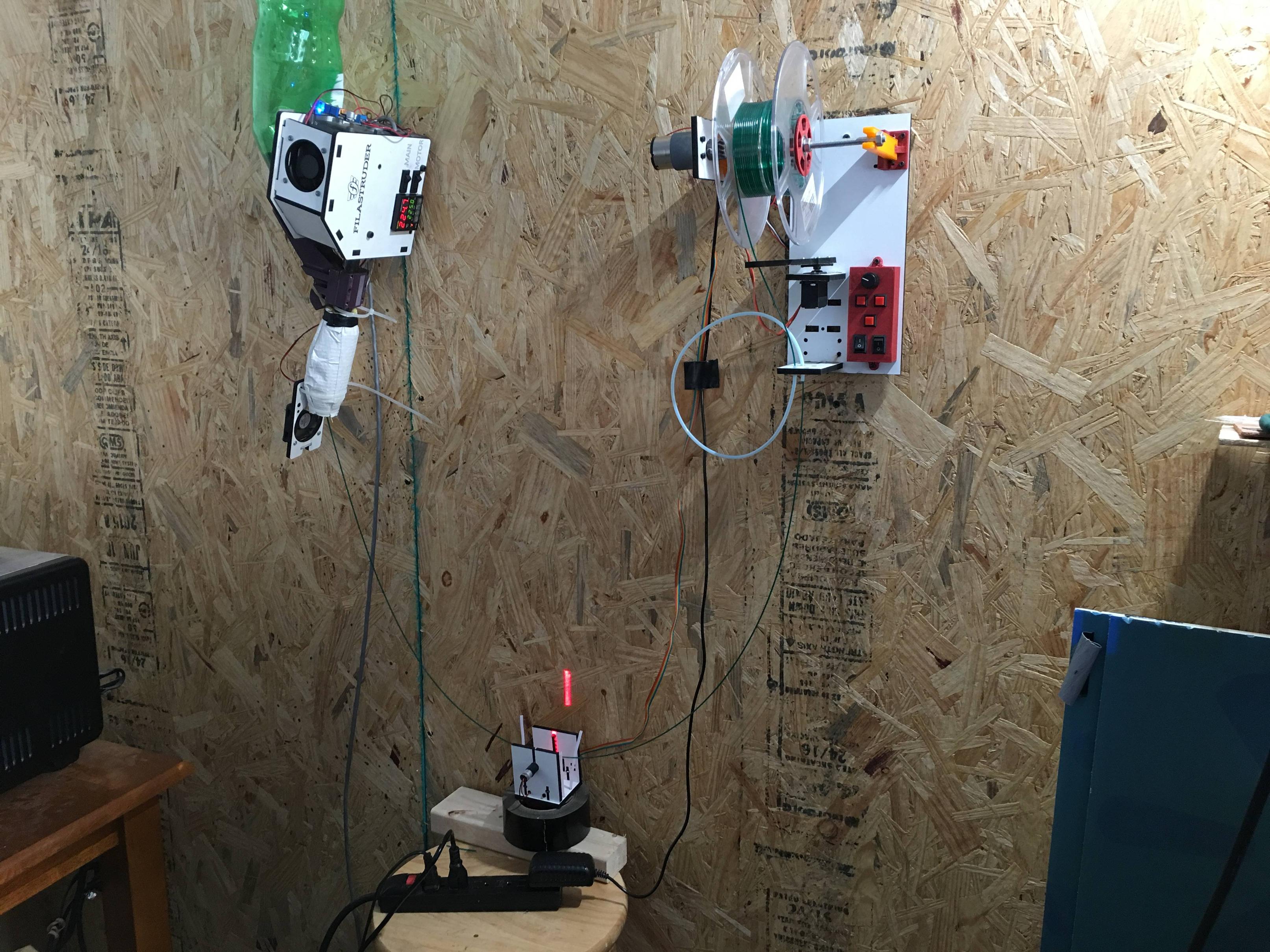

Equipment used: Filastruder 2.0, vertical, with a 15V heater, and 2.2mm nozzle.

Extruded temperature and diameter results: It actually extruded at 190C, and the stock 1.6mm nozzle right on the nose 1.75mm and with little variation but it was too much for the motor. It required average current of ~2A, and occasionally when shearing a pellet in the hopper it wanted to spike up to 2.5A which worried me too much to let it run long. At 225C and a 2.2mm nozzle the average motor current is 1.5-1.7A, and spikes up to ~2.1A on occasion (usually followed by the sound of a pellet shearing in the hopper). At 225C I get between 1.78mm to 1.65mm so not as good as 190C, but a lot friendlier on the motor gears.

Drying this type of pellet is VERY important. If it's slightly wet (and this can happen just by putting a full 1Kg in the hopper and in the couple of hours it takes the extruder the top pellets have already absorbed water) you will get bubbles in your filament. If it's absorbed A LOT of water (such as sitting out in the air a few days) it becomes unextrudable until you dry it. It becomes runny and drips out like a liquid if it's got a great deal of moisture in it.

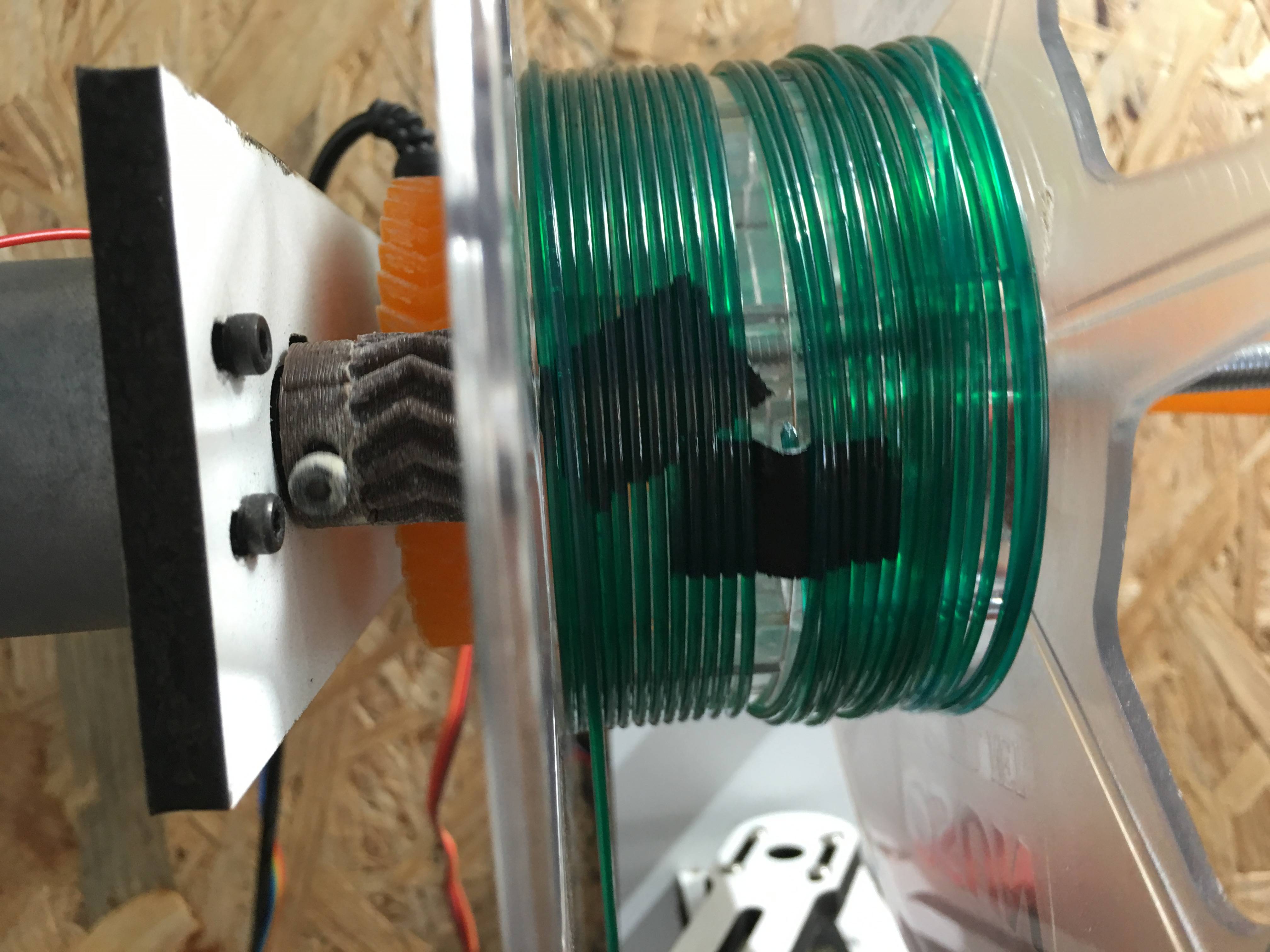

I also used OS3DP's green colorant from (here). His website doesn't mention copolyesters or PETG at all, so I decided to try myself and see what happens. It actually comes out as translucent green and looks really good. We're heading into the season of red and green, and it definitely matches the 'Christmas' green that is so common. I did have sections that were a little darker green than other areas but it was overall more consistent than pellet colorant.

It behaves similarly to commercial bought PETG filament - strong, more durable than ABS or PLA, more flexible than PLA, but less flexible than ABS. Warps MUCH less than ABS, but a little more than PLA. PETG has fantastic layer bonding - that's it's real strength for 3D printing. Here is a Youtube video of tests done that show PETG taking almost as much to pull apart objects along layer boundaries as it does to tear them apart horizontally. That guy has a whole series where he does similar tests with filaments, so you can compare the results with ABS and PLA.

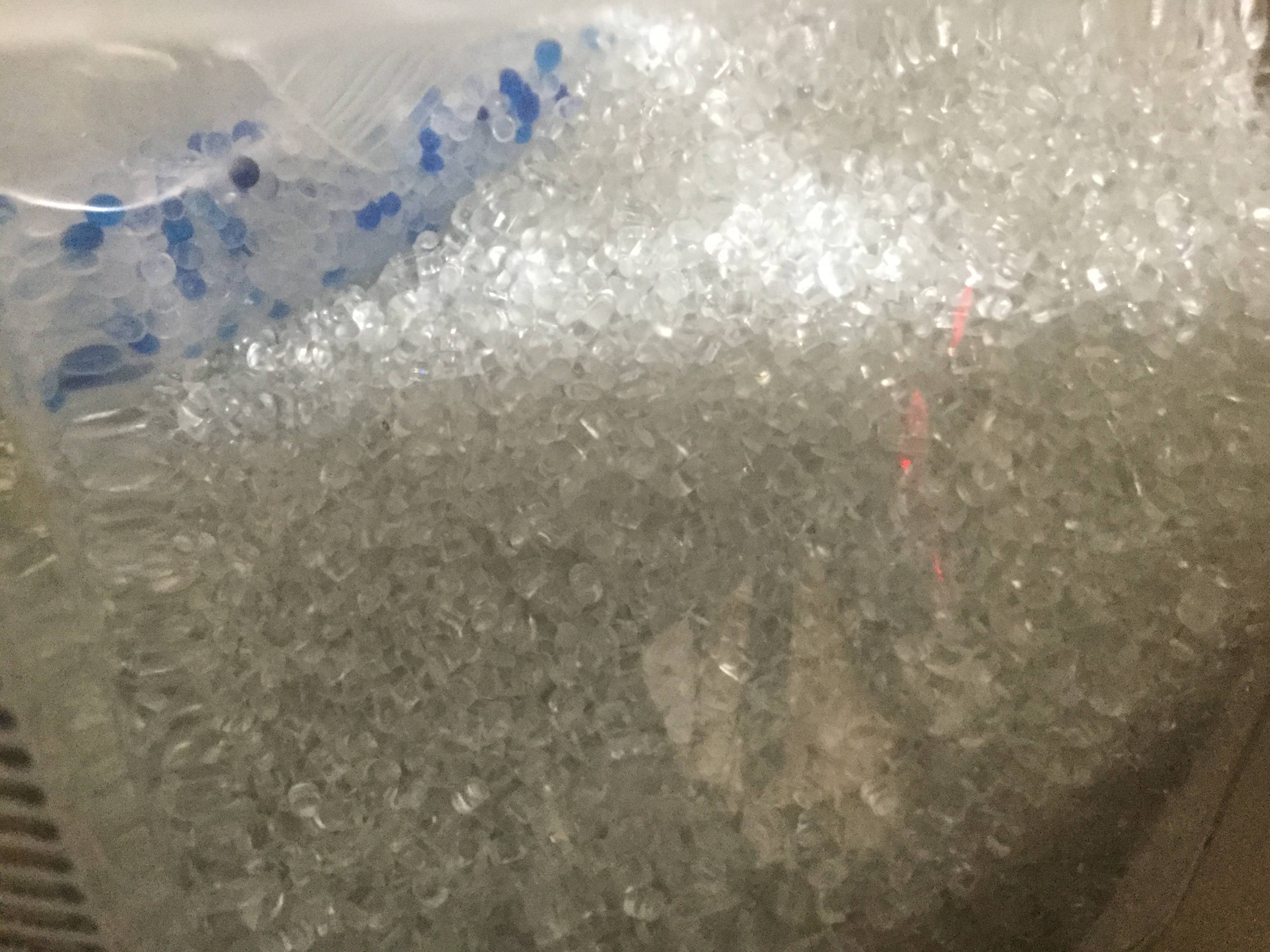

Here are the raw pellets along with some silica desiccant:

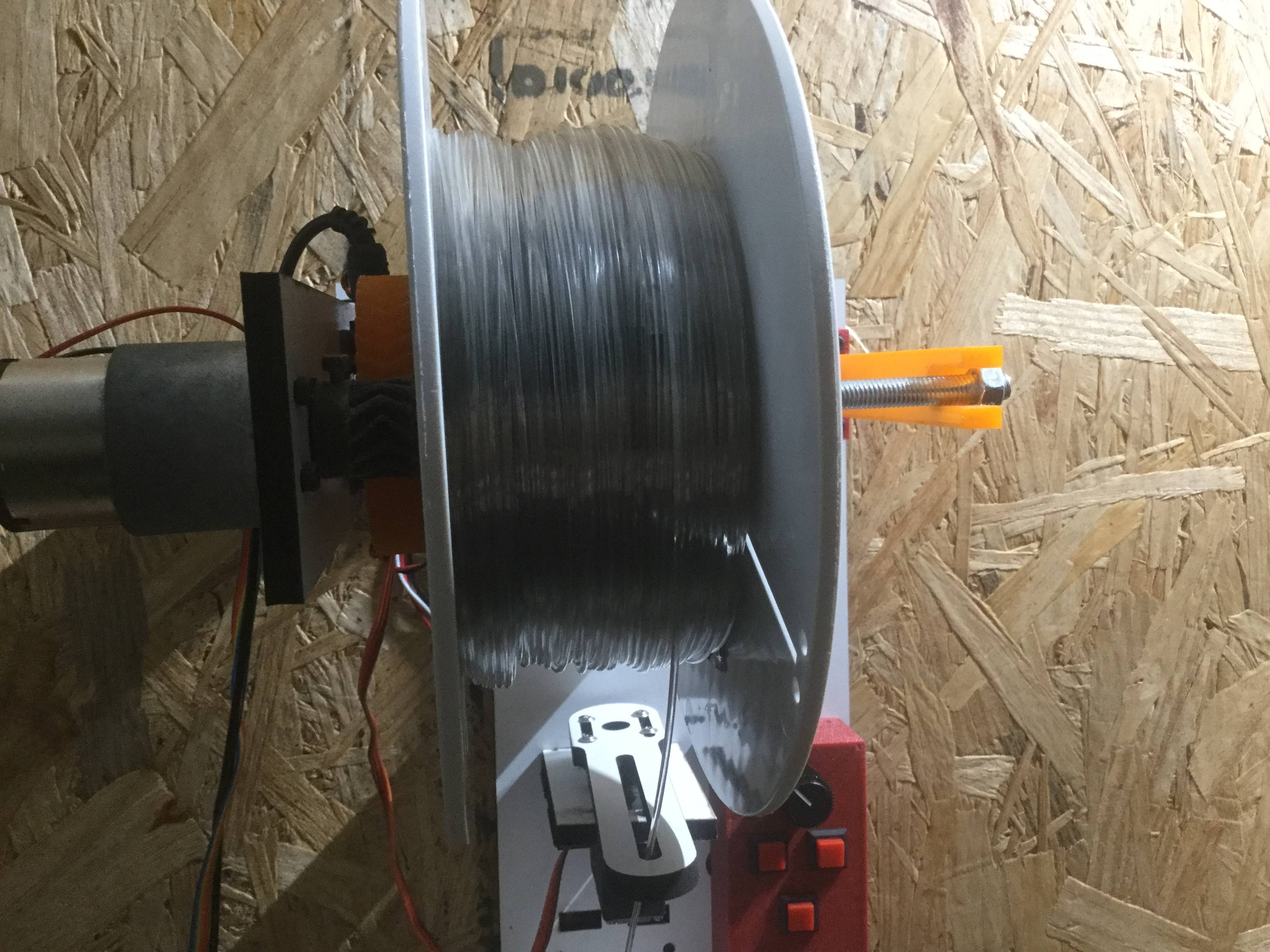

Here it is extruding:

Here is the spool:

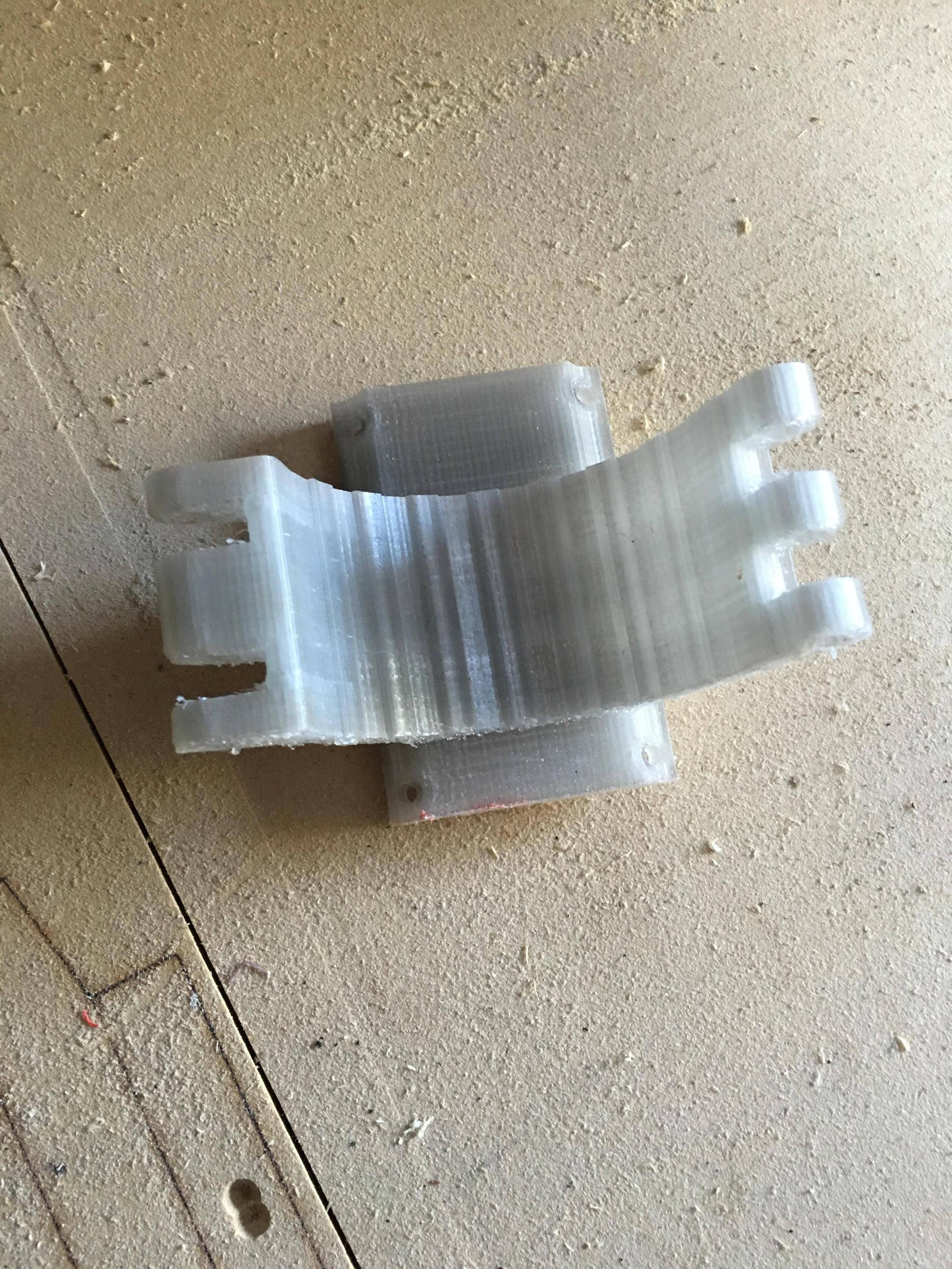

Here are some nut adapters I printed for a new printer build (16.5 inch by 18.5 inch printable area is the goal, Tnuts were $35 a pack, but with these printed adapters I turned a $3 pack of jam nuts into the same thing):

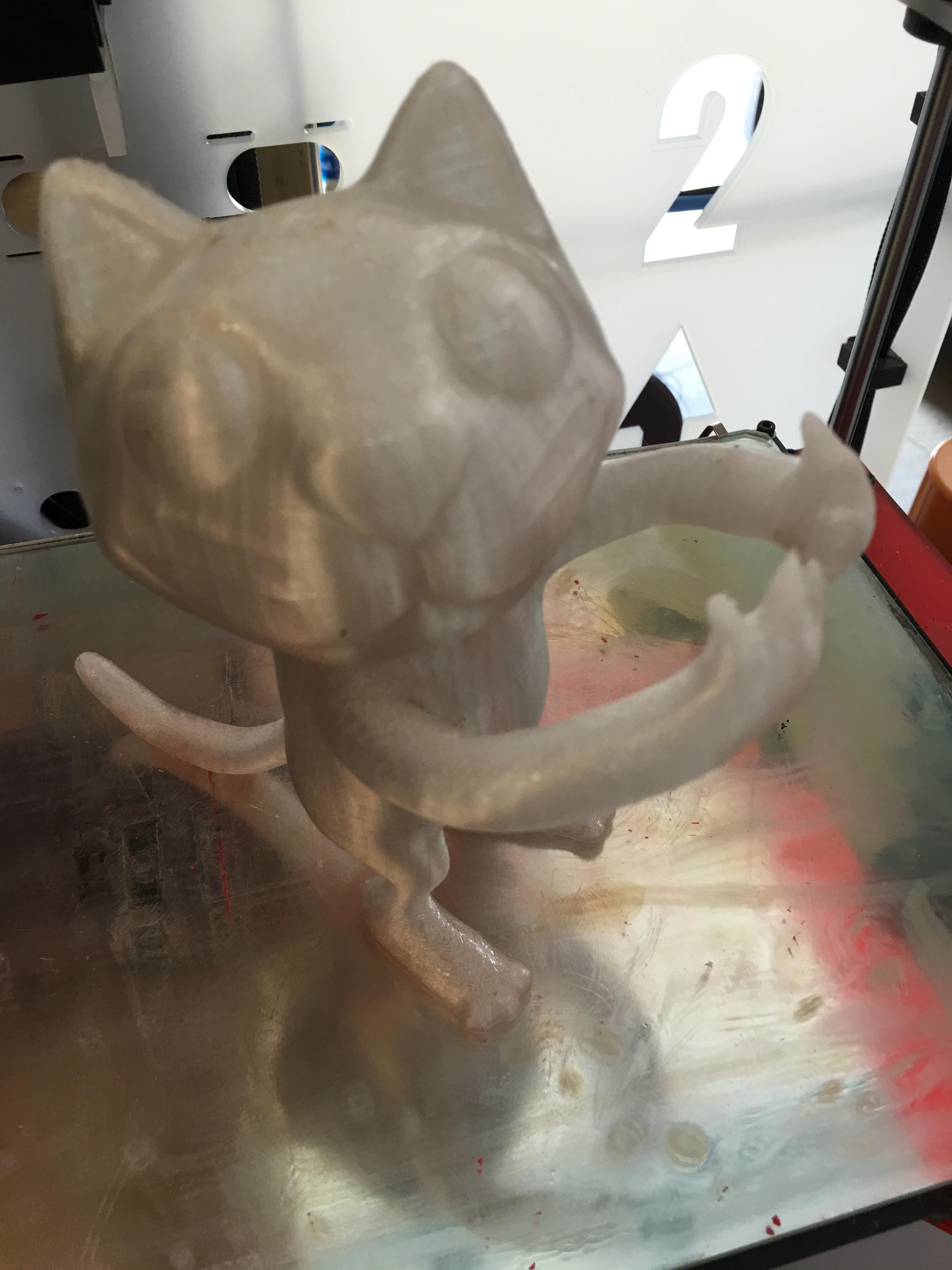

Here is something made for someone else, a cat pen holder:

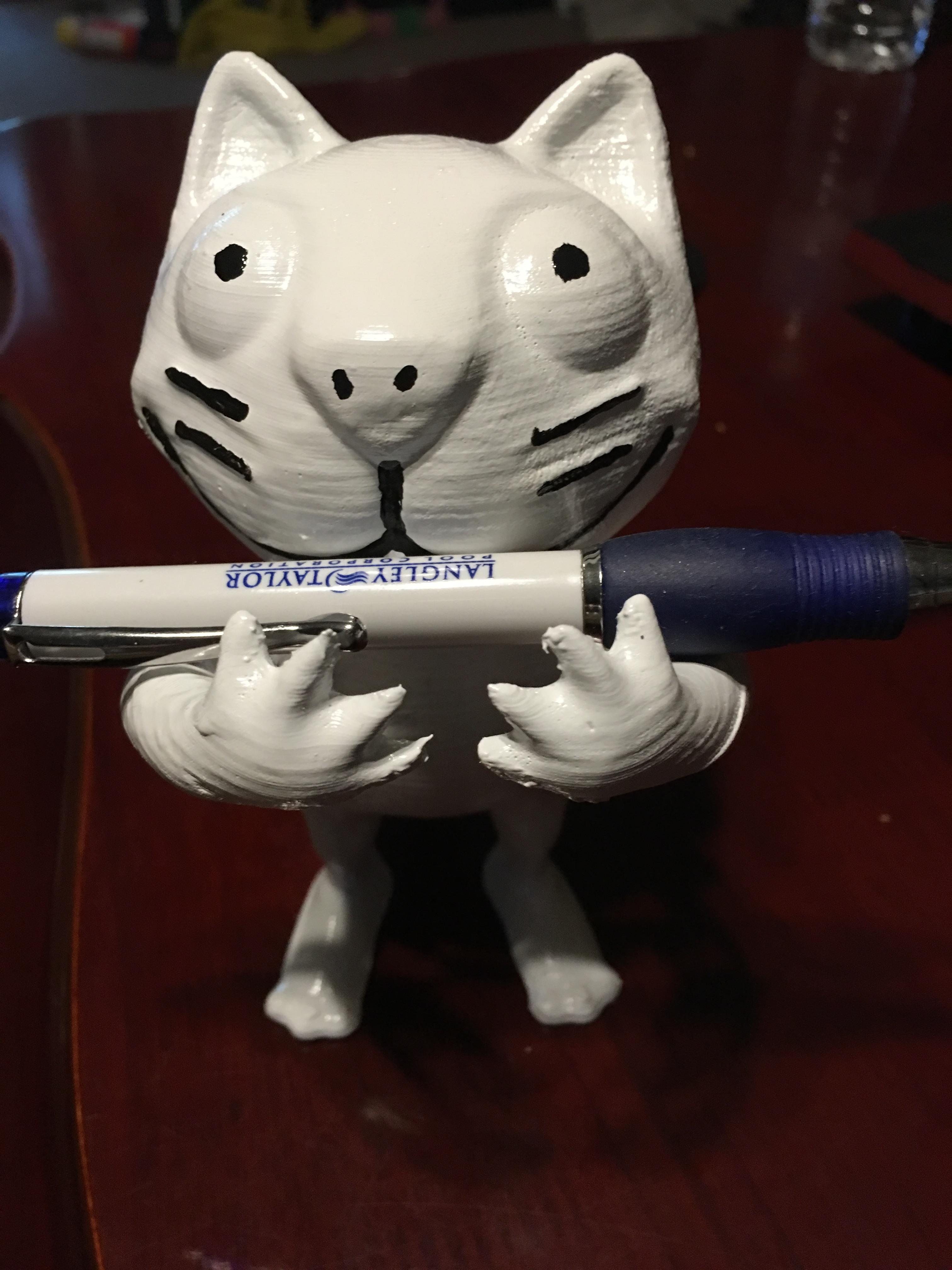

Painted with a white base paint:

Using my minimal painting skills to add some eyes:

Made a new mount for my Mostly Printed CNC - http://www.thingiverse.com/thing:724999 :

Here it is after adding green colorant from OS3DP:

Here it is extruding:

Here it is right after it started going on the spool, you can see how translucent it is by looking at the black tape under the first layer:

Here is the finished spool of green: