Topic: [MABS - Acrylic/ABS] Polylac PA-758

Resin: Polylac PA-758 (MABS, acrylic and ABS)

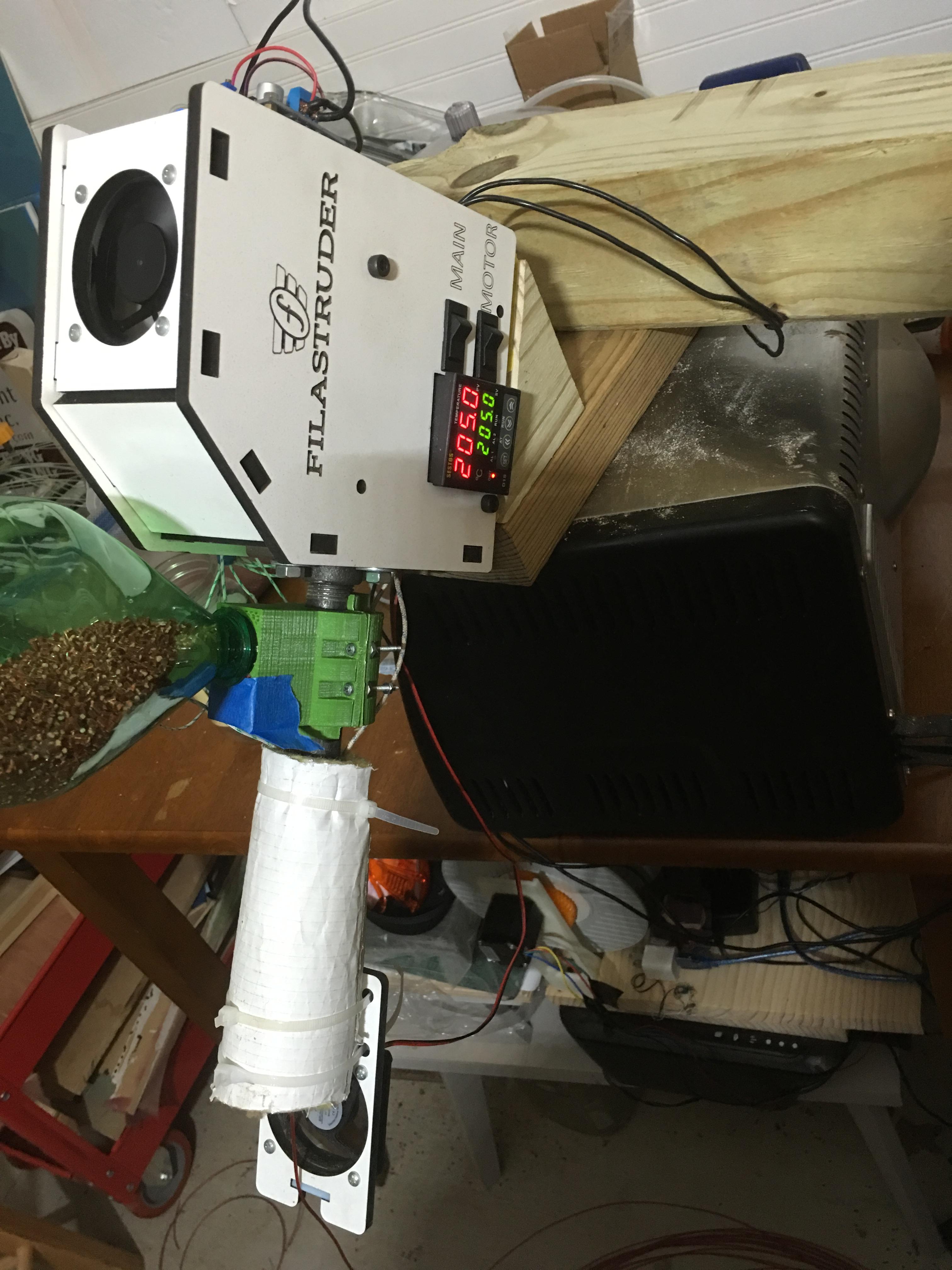

Equipment used: Filastruder 2.0, filament was produced vertically, horizontally, and at 45 degrees. Stock except for the thermocouple which has been replaced with the welded tip kind for higher temperature capability.

Extruded temperature: 205C

Filament diameter and tolerance: Varied with orientation. I received the best consistency with a 45 degree set up (I imagine if I had the Filawinder the vertical would be best - but vertically without a winder resulted in the filament occasionally touching the wall causing a larger diameter section). The consistency was 1.65mm to 1.68mm.

Drying this filament was very important (most ABS pellets don't require extensive drying - but these do). Without extensive drying not only is the exterior rough, but it makes the filament extremely brittle with air voids. After drying this filament remains more brittle than standard ABS (presumably because of the added acrylic.) but not as brittle as PLA typically can be.

Here are the pellets:

Here is the Filastruder at a 45 degree angle (4X4 cut at an angle, with this mounted to it: http://www.thingiverse.com/thing:1508688)

Here is the filament coiled on the floor:

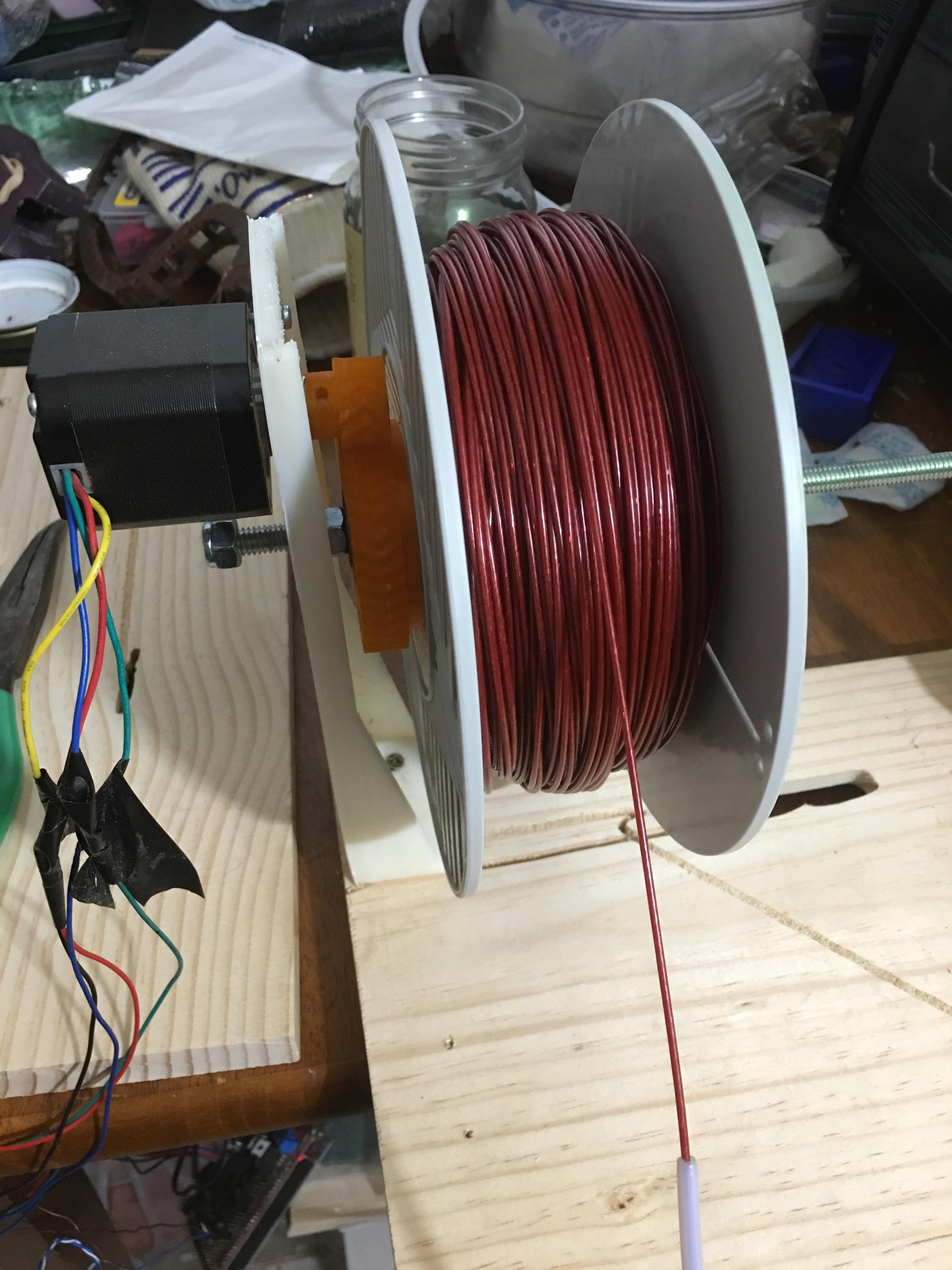

Here is the filament going on a spool, I modified some of the Filawinder STLs to work with a stepper motor and a spare RAMPS board to wind filament after it's done being produced - unfortunately without the laser setup of a true Filawinder it doesn't know to stop pulling on the filament so I can't use it as it's being produced:

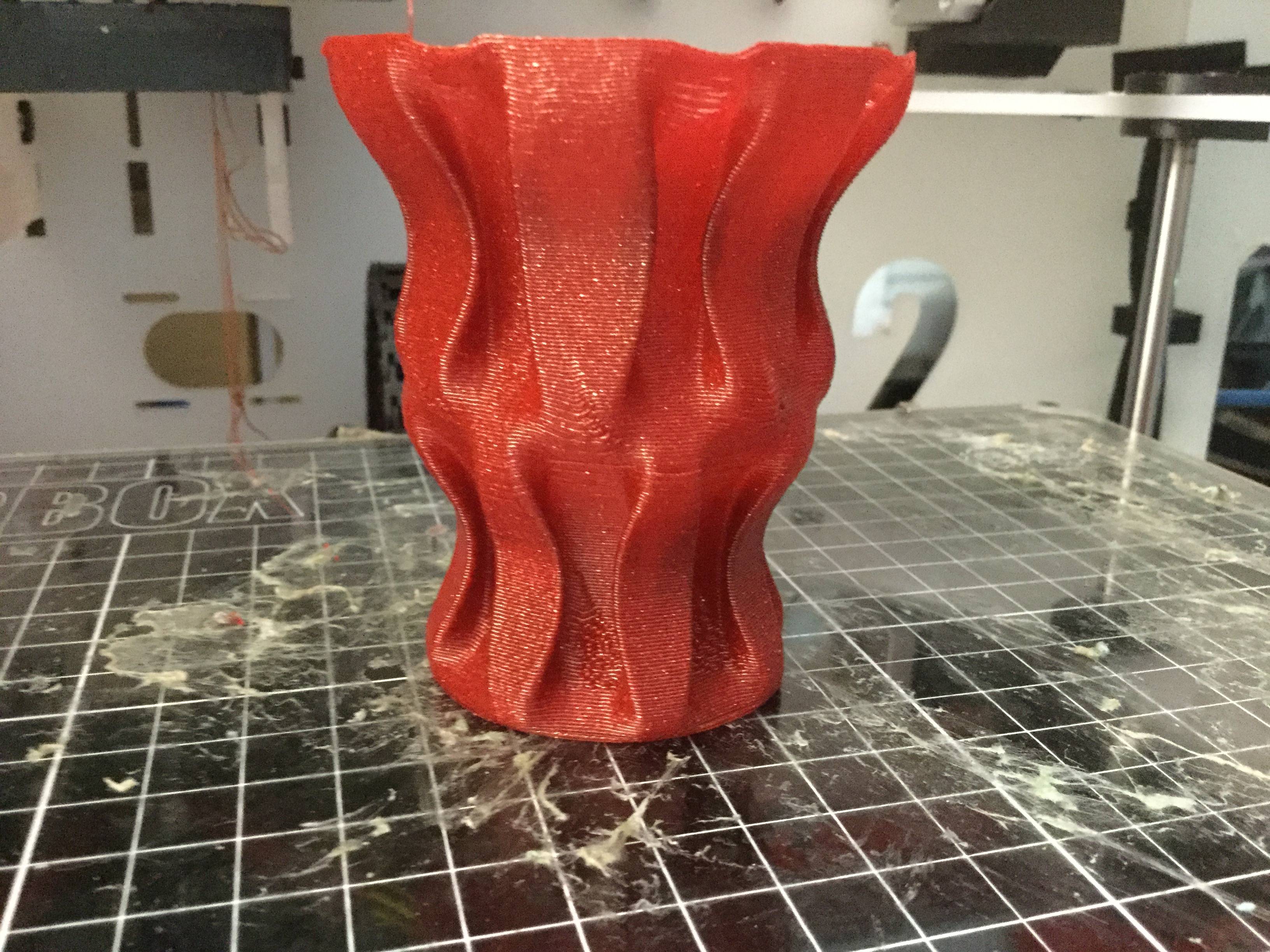

This was suppose to be more translucent than typical ABS so the first thing I tried was a single walled vase:

You can see if something is put inside the vase, but it is closer to opaque than truly translucent. Perhaps with larger layer lines like what Taulman recommends for best transparency.

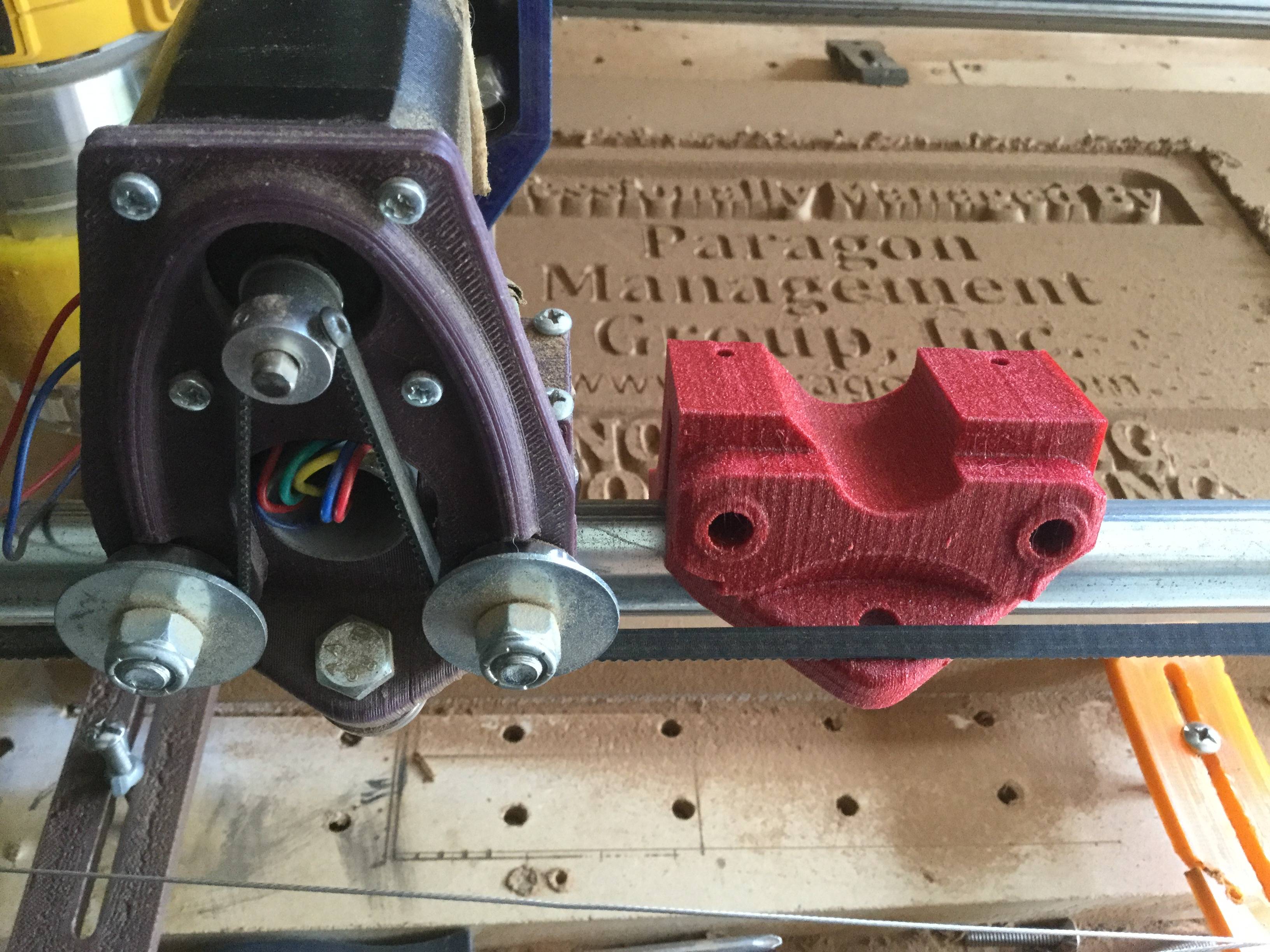

I noticed this plastic was more rigid, less flexible (unfortunately more brittle) than typical ABS so I decided to use it to make the new motor mount designs for my MPCNC (the designer has been churning out new improved parts all the time lately). I used a 75% infill and it came out extremely rigid (what you want on a CNC part). I was worried it might break easily, but if you print with a high infill it seems to overcome the brittleness issue while you can still benefit from the rigidity.