Topic: Thoughts on extending the Da Vinci Jr

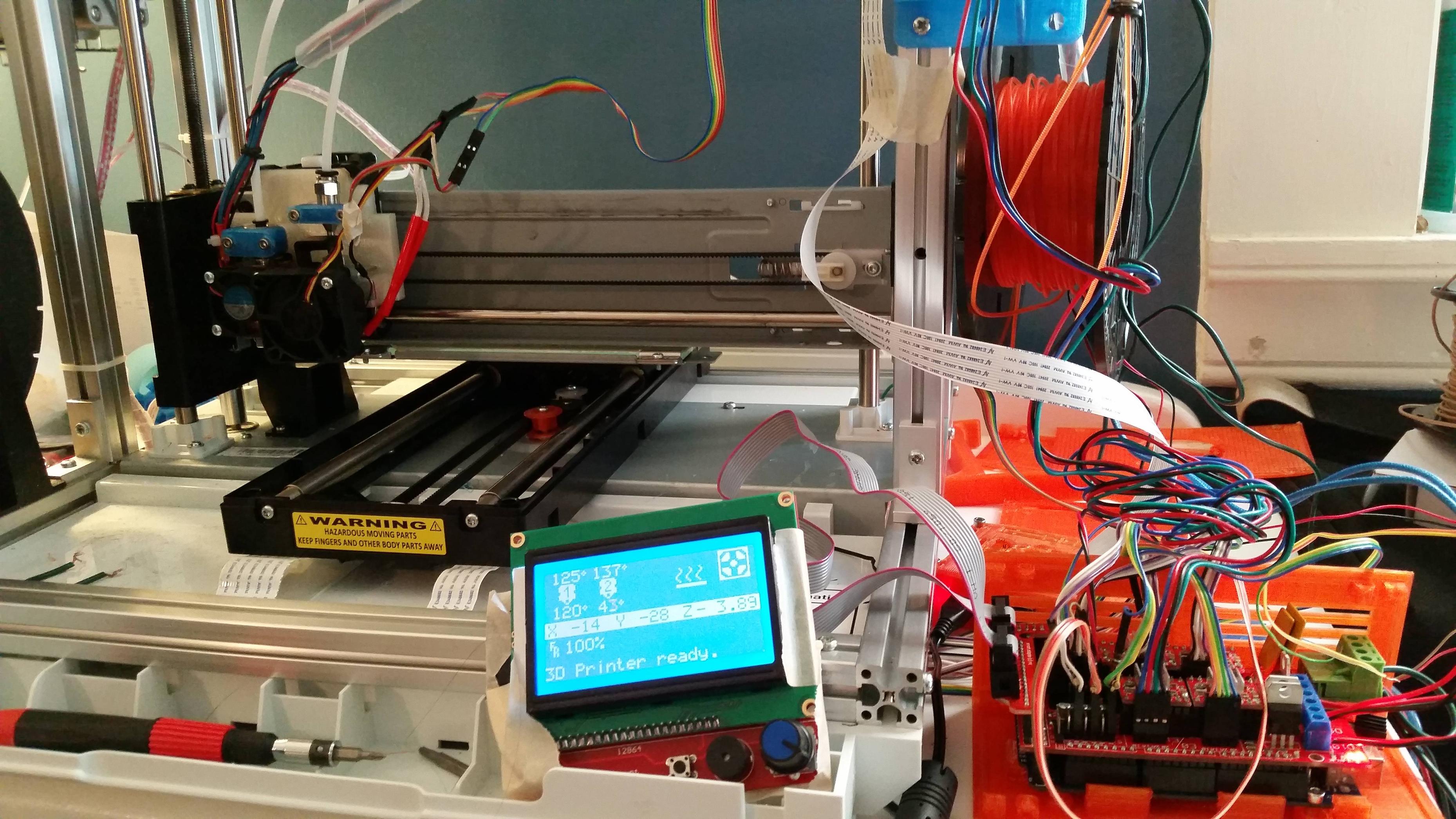

Hey guys. Since my RAMPS conversion (still working on that thread; stay tuned) I've been thinking of other ways I could trick out my Da Vinci Jr.

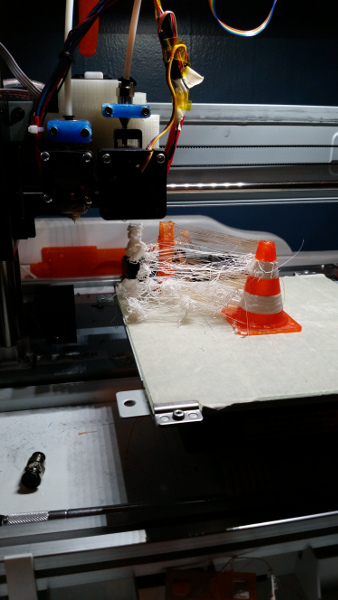

With RAMPS 1.4, my prints are turning out fantastically and I love not having to fuss with those stupid chips. I just printed my son a glow-in-the-dark ghost using Alchement Blue glow in the dark filament. Just this morning I printed v1 of a replacement optical endstop cover (to repair one I busted during my conversion).

Anyway, my thoughts on this have been along two lines:

Adding a second extruder

Extending the print volume

I'm not too interested at the moment in adding a heated bed, though that's a possibility. I know kr15_uk and probably others have added one to Jrs already.

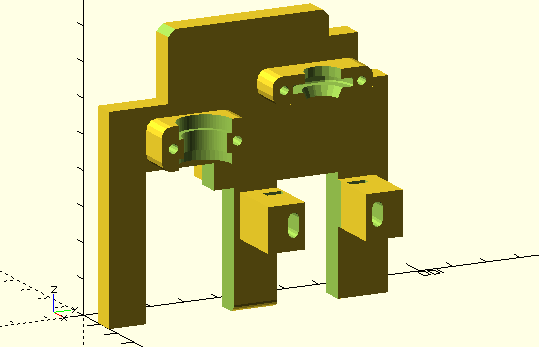

I've done a bit of research on both, and I definitely think that with RAMPS 1.4, adding a second extruder is doable. However, it would cost a bit more money than I want to spend on it right now, as I would need (I think):

A new hotend. E36 V6 runs about US$75. An E3D V6 knock-off would be only about $15, but I'm unsure about the hassle of using a knockoff that doesn't get great reviews.

An extruder assembly. About $35. I could save some money here perhaps and buy the stepper and bolts separately and print the holder, but this is hardly the largest cost and sourcing the parts separately is just annoying

More PTFE tubing and end clamps ($5)

A new power supply. I'm using the stock Jr supply for now, which is only 5A. Plenty for RAMPS and the stock Jr hardware, but not enough to support a second (and higher wattage) heater (~$35).

To design and print a new carriage bracket for the dual hot-ends

So the BOM for that project is adding up quick, and I don't want to tackle another $130-150 project right now. Definitely I think a possibility though.

On the other front, extending the actual print volume, I have some other thoughts. There are of course three axes, each taking a different approach on the Jr.

Y-axis

The Y axis seems like the easiest target for extending the printer.

This would require removing the back panel and (re)moving the front LCD (mine isn't useful or present anymore anyway).

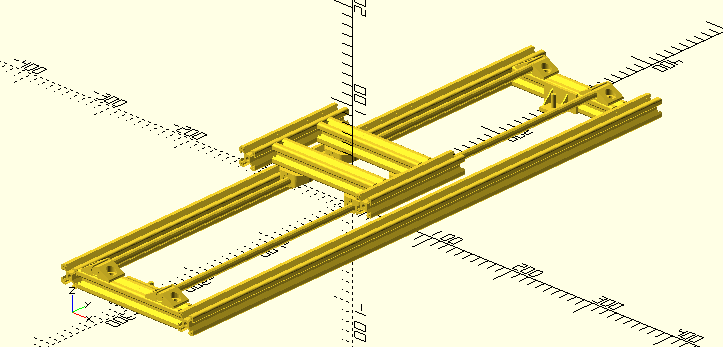

However, the whole Y gantry assembly would have to be modified or changed out somehow. The Y endstop is at the back of the printer and clips into the Y gantry base. Easiest thing to do would probably be to remove it entirely and print new parts to make a larger version of it.

I see two options from there:

Buy a new belt and longer glide rails, install them in the newly (printed) gantry assembly, reusing the existing gears and pulleys with the newly-printed Y gantry assembly. This should be a pretty reasonable and inexpensive (~$30?) modification as long as you can source the rails without too much trouble

Replace the stepper gear and convert the Y axis to some kind of direct-drive without a belt. I'm thinking here about something similar to the RepRap Snappy's XY drive https://github.com/revarbat/snappy-reprap/wiki/Assembly. This conversion should be entirely printable (cheap!) but requires a bit of designing, plus the troublesome part of pulling the gear off the stepper (or replacing the stepper entirely at a higher price point).

Z-axis

Extending the Z-axis seems like the next easiest target. It should be possible (as far as I can tell without trying it) to print 20x20mm V-slot extenders to raise the top of the unit a few inches, swap out the vertical rails (three: two on the left side, one on the right) with longer versions using the same hold-fasts as now, and swap out the left side drive screw with a longer one.

Sounds like a simple matter, but it requires non-printable metal parts, though they should be pretty reasonably priced.

X-axis

I don't have a sound plan for this one yet. It would have to involve removing the right side of the unit entirely, extending the V-slot rails, probably moving the existing V-slot upright outward to the new edge, then somehow replacing the entire X gantry. On the bright side, changing the X dimension won't necessarily require modifying the bed bracket because the glass clips are parallel to X. A new sheet of glass could be added that (maybe temporarily) overhangs the bracket until an additional bracket or supports can be printed.

Needless the say, this extension would be a lot of work. The structure of the X gantry and the placement of the uprights makes "simple" extension impossible. A new gantry would have to be fashioned, or the entire drive mechanism changed out.

I've thought that maybe the X drive mechanism could be switched to use a geared rack, on which the X stepper itself and the hotend are mobile. Something similar to the X/Y drive mechanisms of the Dollo [uri]http://dollo3d.com/[/uri].

Anyway, I'm probably crazy even to propose any of this. Thinking about it, the Z extension is probably the easiest modification to make, but I find myself maxing out my XY dimensions far more often than the Z, so it's probably not as useful.

Has anyone else given thoughts to this kind of mod, either on the Jr or another machine? Anyone have real experiences doing so?