Re: Solidoodle 2 upgrades

for this last set, i seemed to have to really crank the tension down to get the gear to grab. it is possible it is too high. On that note how do you determine the right tension? Every guideline I've seen just say play with it until it works. What works when extruding with manual controls, doesn't when you do real prints.

Hmm idea. i should write up a bit of manual gcode to emulate extrusion during a print (slow extrusion followed by quick retract/extrude for anti-ooze. Repeat 5-10 times to test the tension? would back-pressure at the nozzle be something i need to account for?

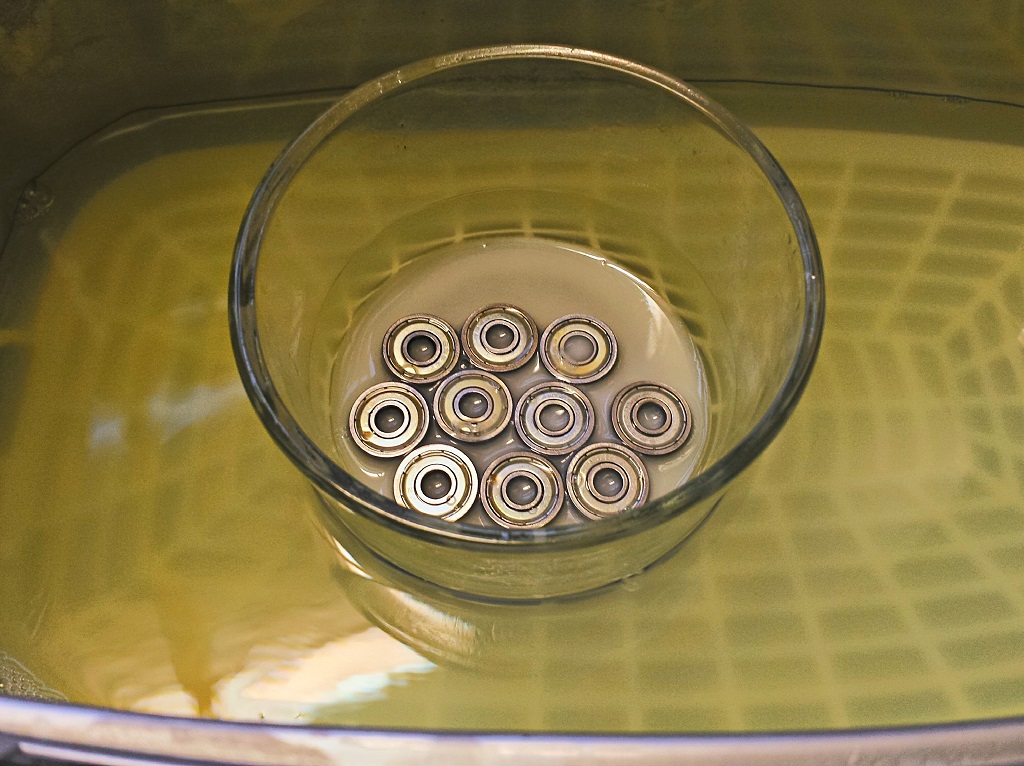

The motor does get quite hot, but not really burning hot though. The dust never seems to show signs of melting so i assume the print wouldn't be warping? The fan on the extruder stepper heatsink is a bit sick, i have to flick it a couple of times when i first turn it on to get the bearing to seat right and stop buzzing. It has never stopped and it does pull a lot of air.

the build chamber usually runs about 50C.

-edit-

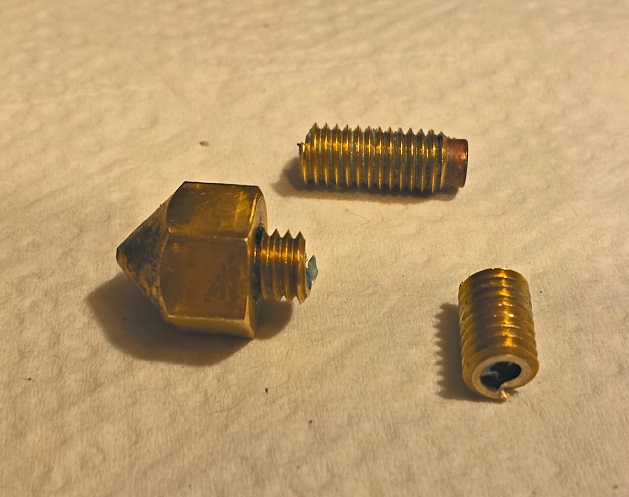

So, perhaps the collapsed bearing is a symptom not a cause as some have been suggesting. Perhaps my nozzle is a bit clogged causing excessive backpressure. (plastic extrudes straight, but i have a real difficult time manually pushing plastic through it, sometimes fracturing the filament. ) therefore i have to add excessive tension which causes parts to warp and/or the filament to sheer causing the chain reaction.

I did disassemble my hotend to get the wood piece off. perhaps i a piece of the peek broke loose when i screwed it back end partially blocking things upstream from nozzle. I will try to examine it tonight. I am thinking of giving it a good cleaning via acetone injection. it seems acetone dissolves peek so i will have to separate again.