Topic: E3D V6 5 clogs in 5 attempts

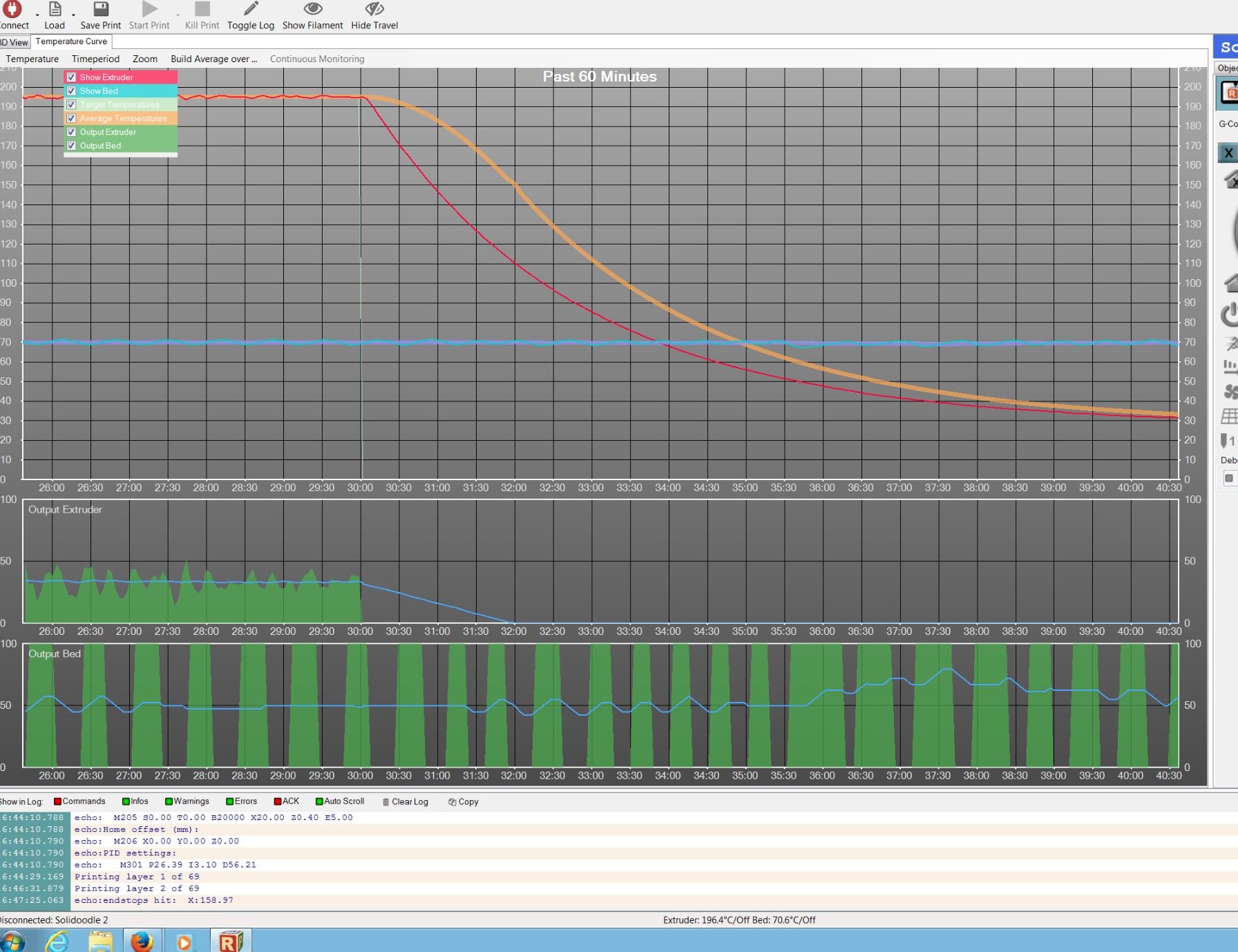

I've had my printer for about 18 mo and my E3D for about a year. I have printed both PLA & ABS with what I consider pretty good results - (Lawsy's carriages came out primo!) getting better, until recently.... I gave me and the printer a week off, cuz it clogged 3 times in 3 consecutive tries last weekend - 2 ABS & 1 PLA. The temps are right, same I have been using for a while. Tried again today - 2 clogs in 2 attempts. PLA 185/70. Prints for about 8 - 12 min, then the filament clogs. Machine still goes like it's printing, temps OK and all, but no filament. Space between the nozzle and the print keeps getting larger.

Was printing a circular thingy - printed about 3 1/2 solid layers then it went to infill (set at default) and the results looks like somebody frizzed their hair, then space...... All 5 clogs have happened in the midst of printing. The machine pays no attention - the temps stay up and the empty layers run off. The filament was sealed new til about 3 weeks ago.

Any ideas?

This week I'm probably gonna buy an E3D Lite. Was gonna buy a new nozzle, thermistor & heating element, almost just as inexpensive to get a Lite version. All I'm gonna print for some time is ABS & PLA anyway.....

TIA

Ski