Topic: [PLA] - 4043D

!!! DRY DRY DRY !!!

Regardless of where you get your PLA, 1st thing you do is get it dry.

Even if it comes per-dried (and the supplier below does just that) you should still dry your PLA prior to use.

Failure to do so ABSOLUTELY WILL result diameter/extrusion rate/uneven color mix leading you to suspect anything else but moisture in your filament. So before you continue on reading, put your PLA into an oven or in direct hot air flow and read the rest.

Thank you.

PLA - 4043D

================================================================

PLA - 4043D Biopolymer.

Colorant/masterbatch: BLUE recommend mixing at a 50:1 natural to colorant ratio.

NOTE: Adding colorant will decrease diameter by about 0.05mm-0.1mm depending on how well it gets mixed.

Supplier osprintingllc.com.

Thermal Characteristics Melting Point 145-160ºC

Recommended Extruder nozzle temp: 155 C - 170 C

Typical drying conditions are 4 hours at 175ºF (80ºC) to insure perfect condition.

Requires cooling to maintain diameter. Vertical extrusion should consider to increase nozzle diameter by 0.2mm if undersized.

Extrusion rate 3-5 inches per minute at 170 C

================================================================

Machinie used:

Filastruder

Machine MODS:

Stock 1.75mm nozzle with filter drilled to 1.8.

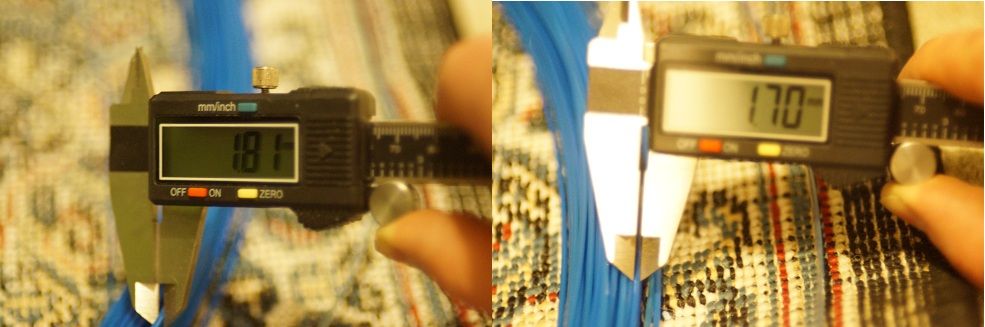

Diameter achieved 1.70m-1.80mm 4-5 feet off the floor for coiling. No filament winder.

Extrusion speed: 3-6 inches per minute

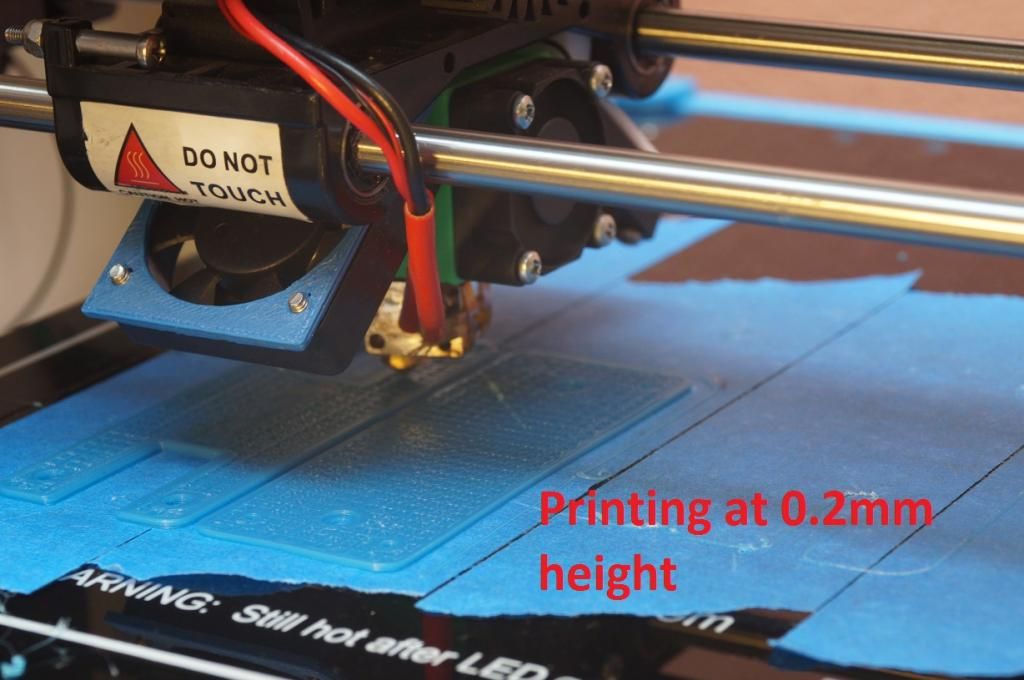

PRINTER:

Robo3D with E3D all metal V5 hot end 0.4mm nozzle.

================================================================

Satisfactory level from 1 to 10:

Extrusion rate: 3

Diameter tolerance without automatic winder: 5 (7 for clear with no color)

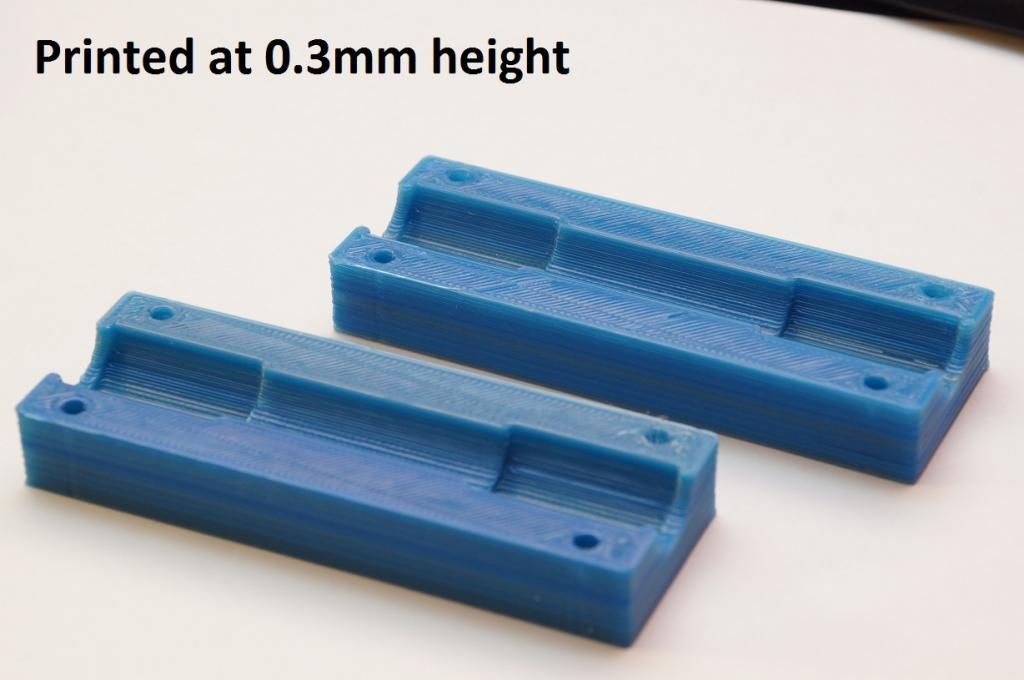

Printing 10

================================================================

Here is what it looks like with colorant mixed.

After 9-10 hrs of run.

Size vary from around 1.7 to 1.8 (more or less depending on the angle at which filament is hitting the floor)

With use of Filawinder, tolerance expected to drop down to 1.73mm-1.78mm

www.osprintingllc.com offer free shipping and have lots of bundle deals that save you even more.

my 3d models http://www.turbosquid.com/Search/Artists/tonycstech