Topic: Non-constant extrusion issues

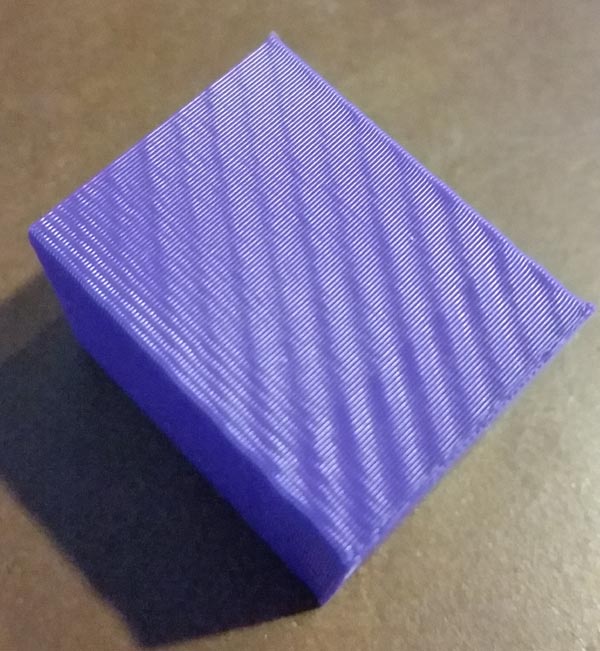

So I recently installed a new E3D v6 hotend on my Solidoodle 2 Pro, and along with it came a problem that I haven't seen anyone else have. When the extruder motor turns, it turns in steps. This has been normal behavior for my printer since I've gotten it, even though these steps seem a little large. This never used to be a problem until I installed the E3D, and now it is making lines bumpy. Whenever the motor makes a step, it pushes out more plastic, creating a wide part of a line. Here are 5 lines surrounded by a skirt that I just printed:

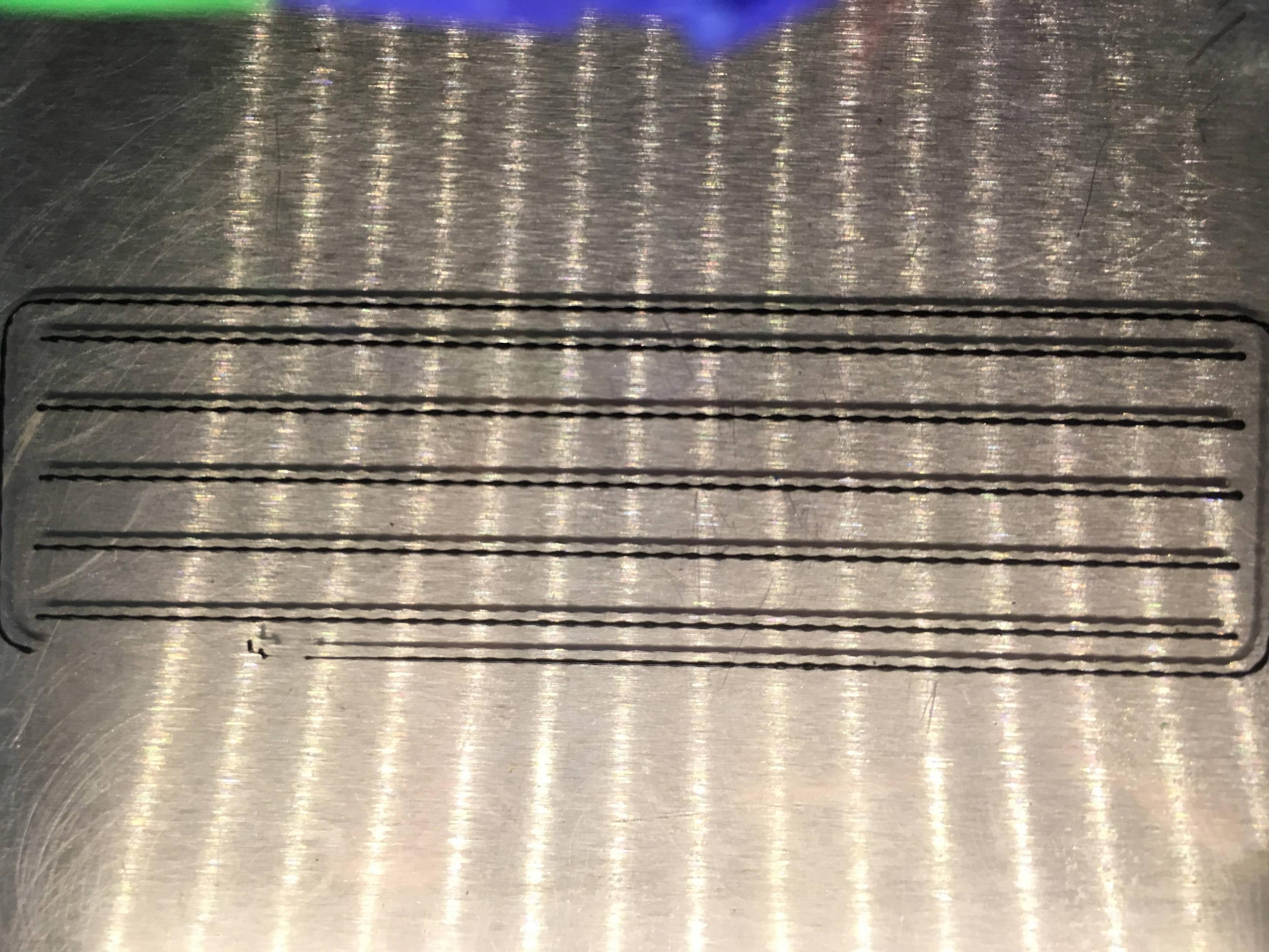

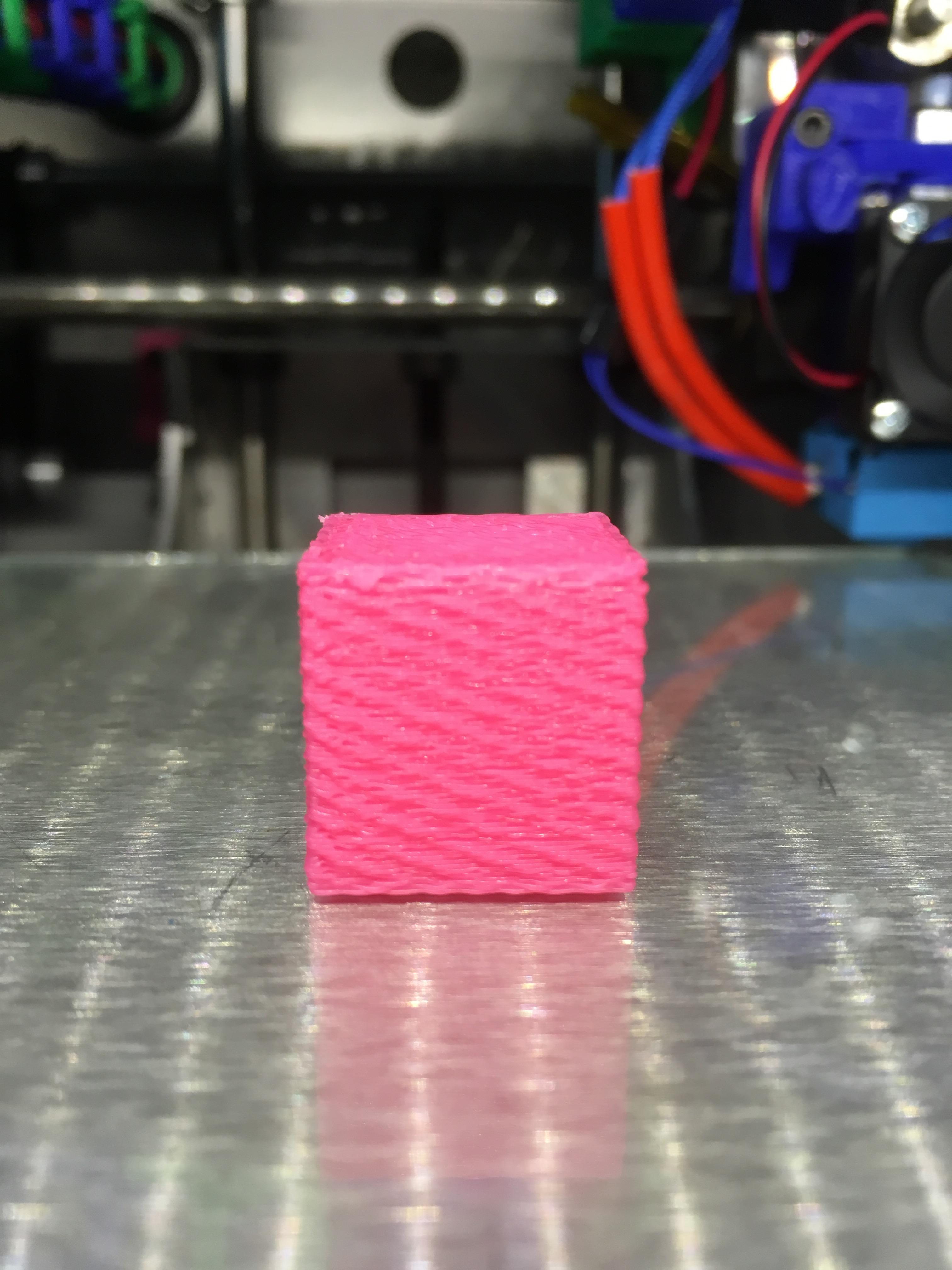

This doesn't only happen with lines. Here's the first print that I did after installing the E3D (a hollow cube):

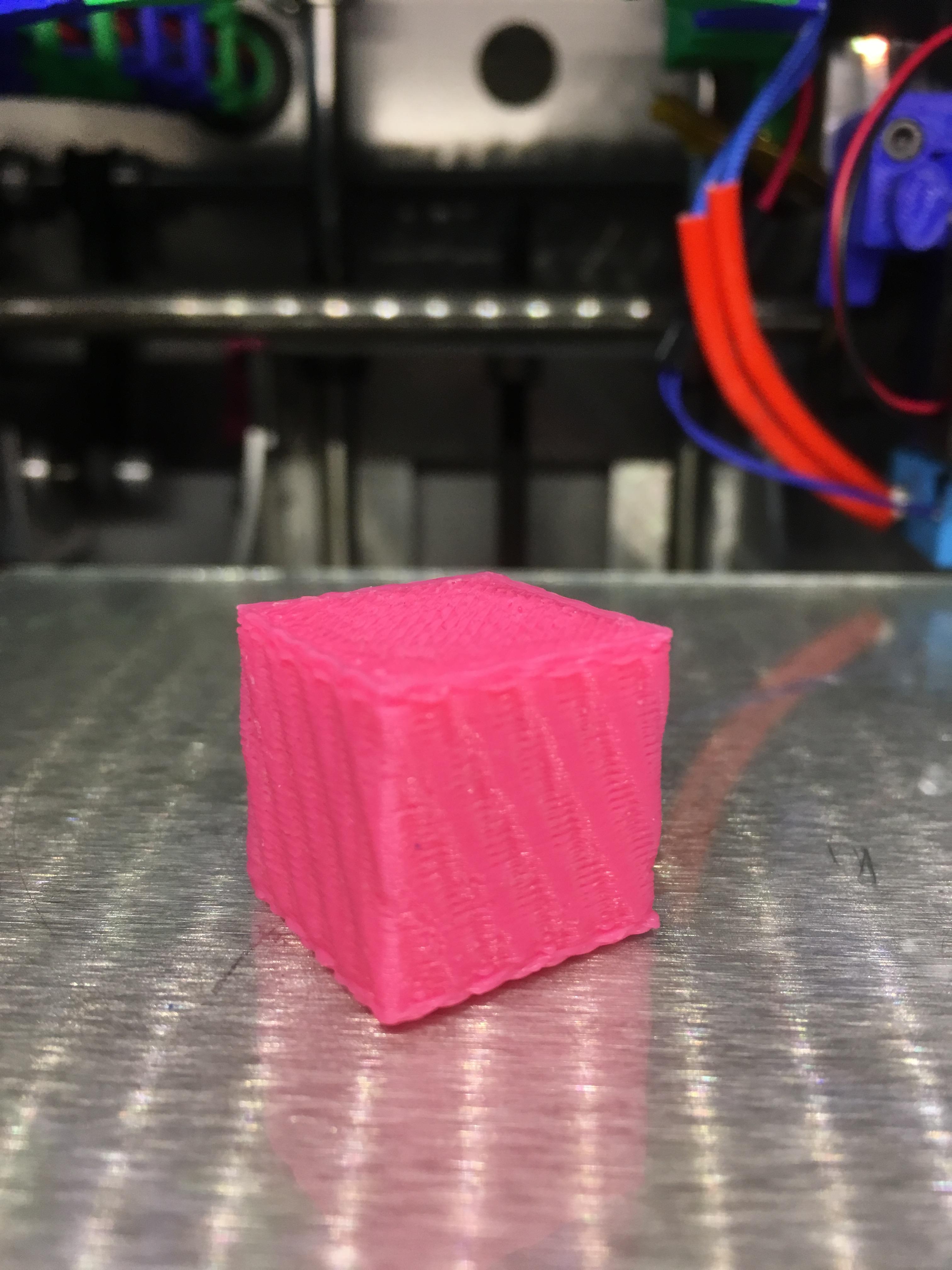

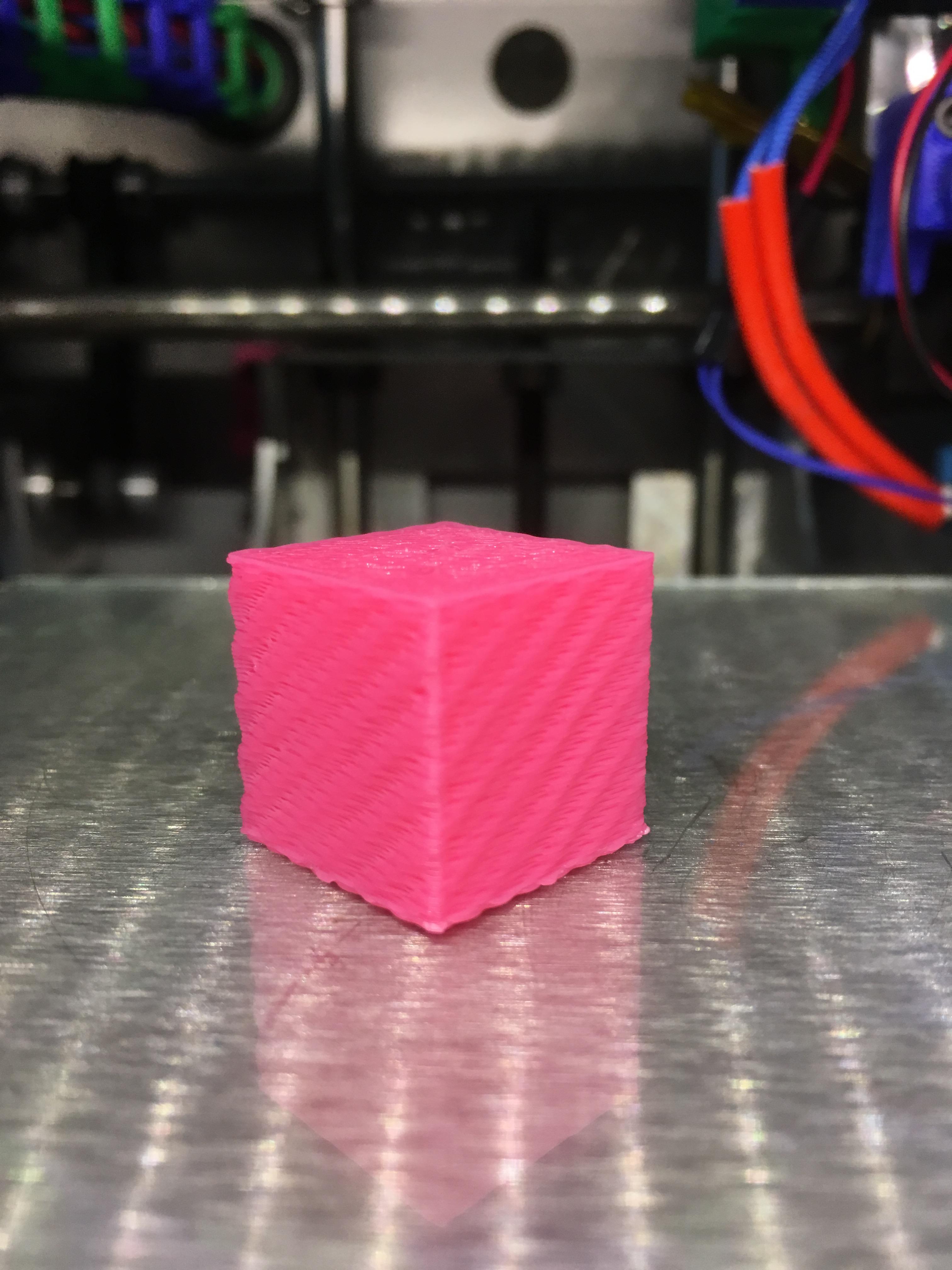

After that, I tried increasing the speed from 40 m/s to 60 m/s, and printed the same model. This was the result:

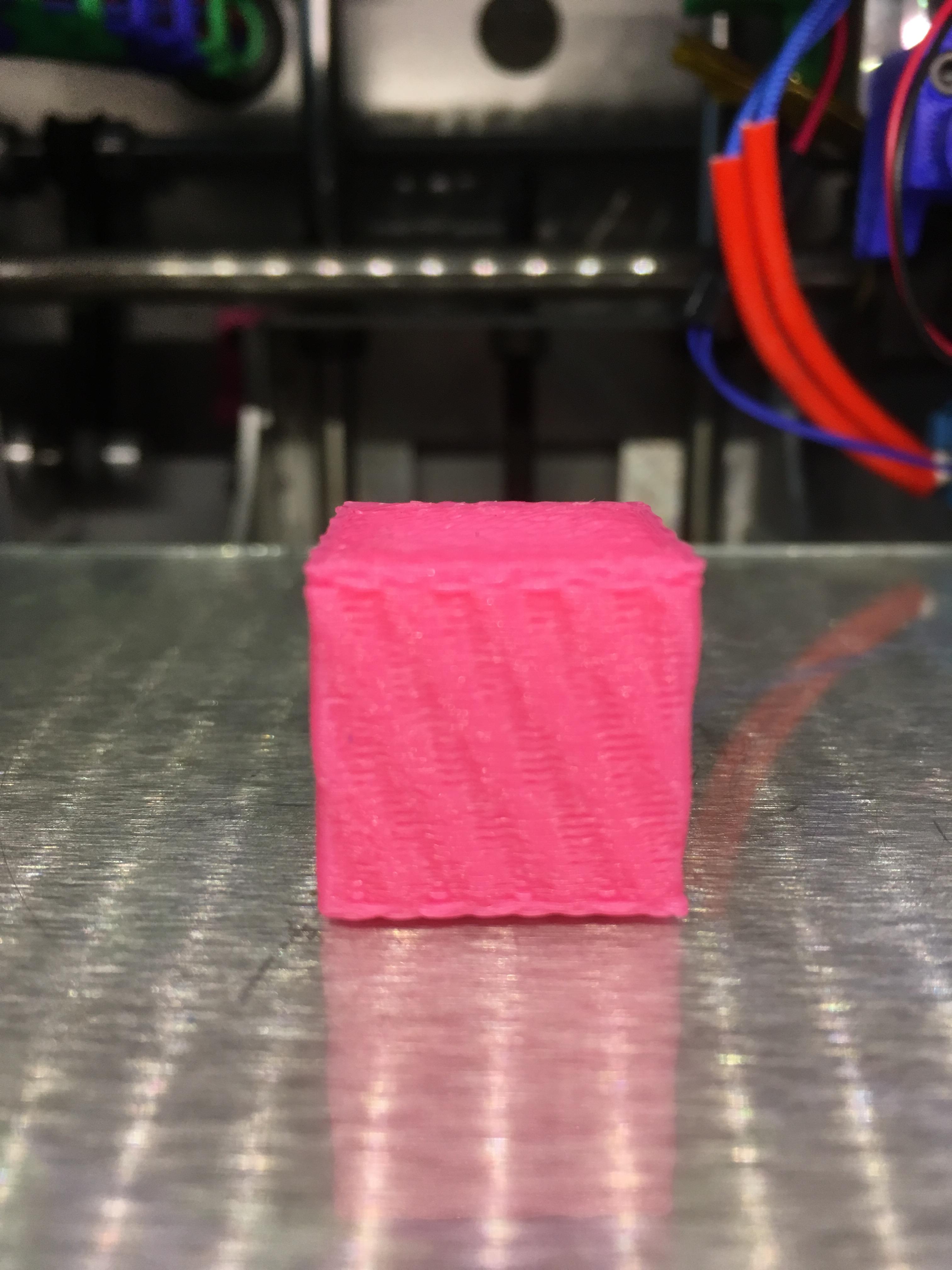

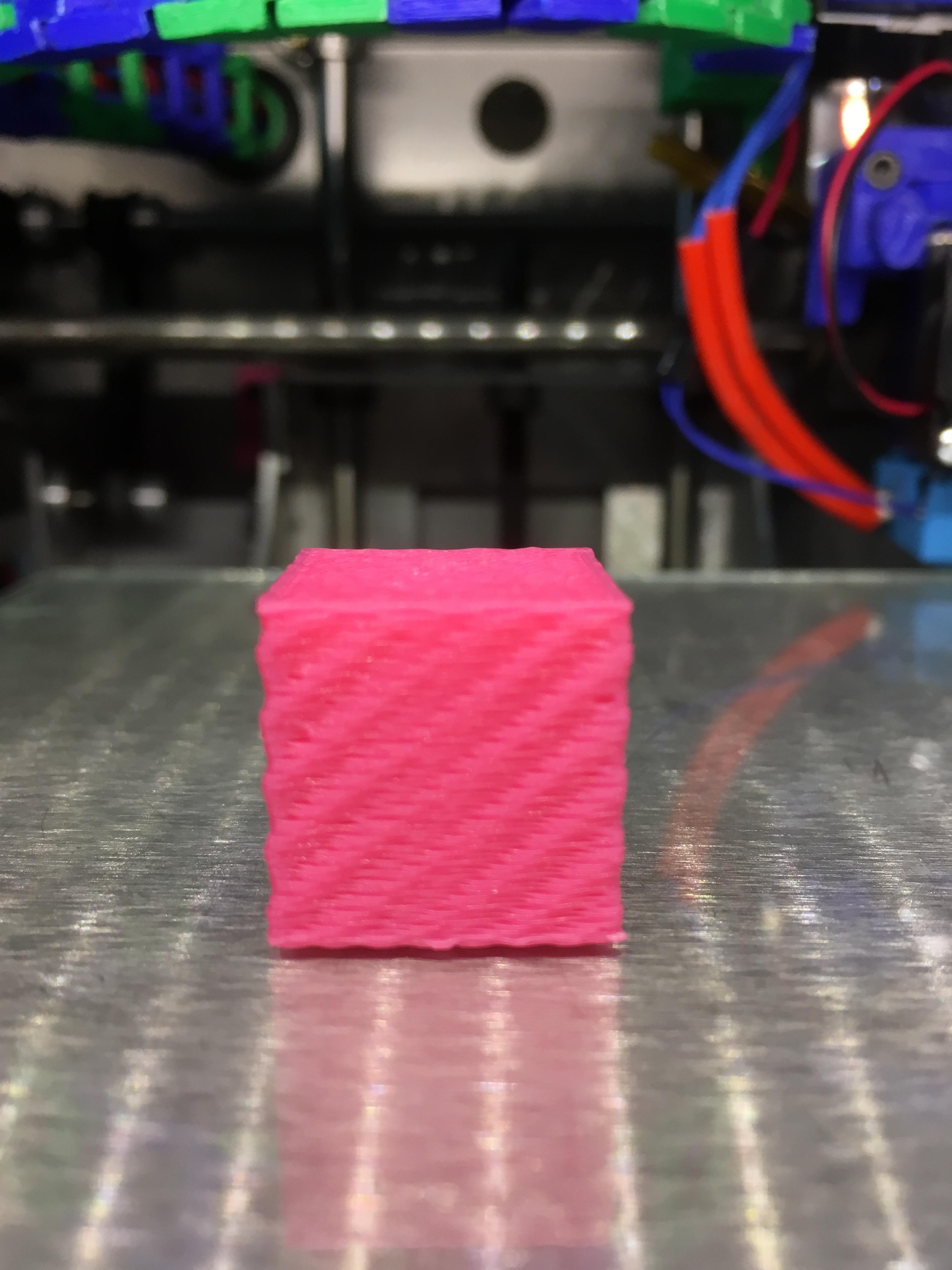

I then brought the speed back down from 60 m/s to 45 m/s, and tried a different model (a solid cube with 20% infill)

All in all, I'm stuck. Nobody seems to have a solution, or even has had this problem. Every time I search about it, the results are about clogged extruders or the sort. Any help or insight would be appreciated.

Here's some additional information:

I use Hatchbox 1.75mm ABS filament, and I've tried different colors.

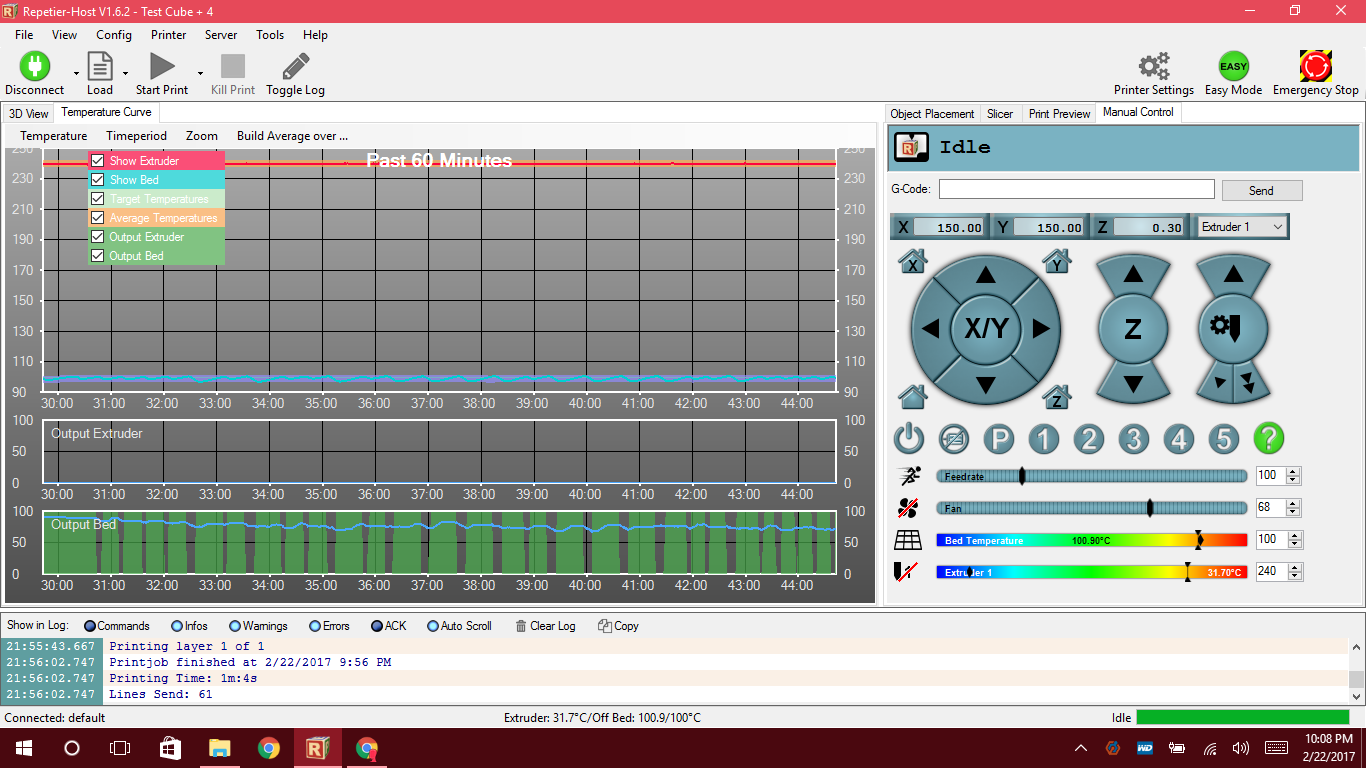

I print at 240 C according to the E3D thermistor, and have a glass hairspray-coated heated bed at 100 C.

Here's the temperature curve during a print:

I use lawsy's jigsaw replacement mk5 with feitcounter's mk5 E3D body and bradjshannon's mk5 better locking arm.

Also, I'd like to add that I have not calibrated the flow rate. I cannot get an accurate measurement of thickness with the bumpy nature of the lines. I have, however, adjusted the flow rate to see if it fixes the problem. It did not.