Topic: Bed screws

Hey everyone,

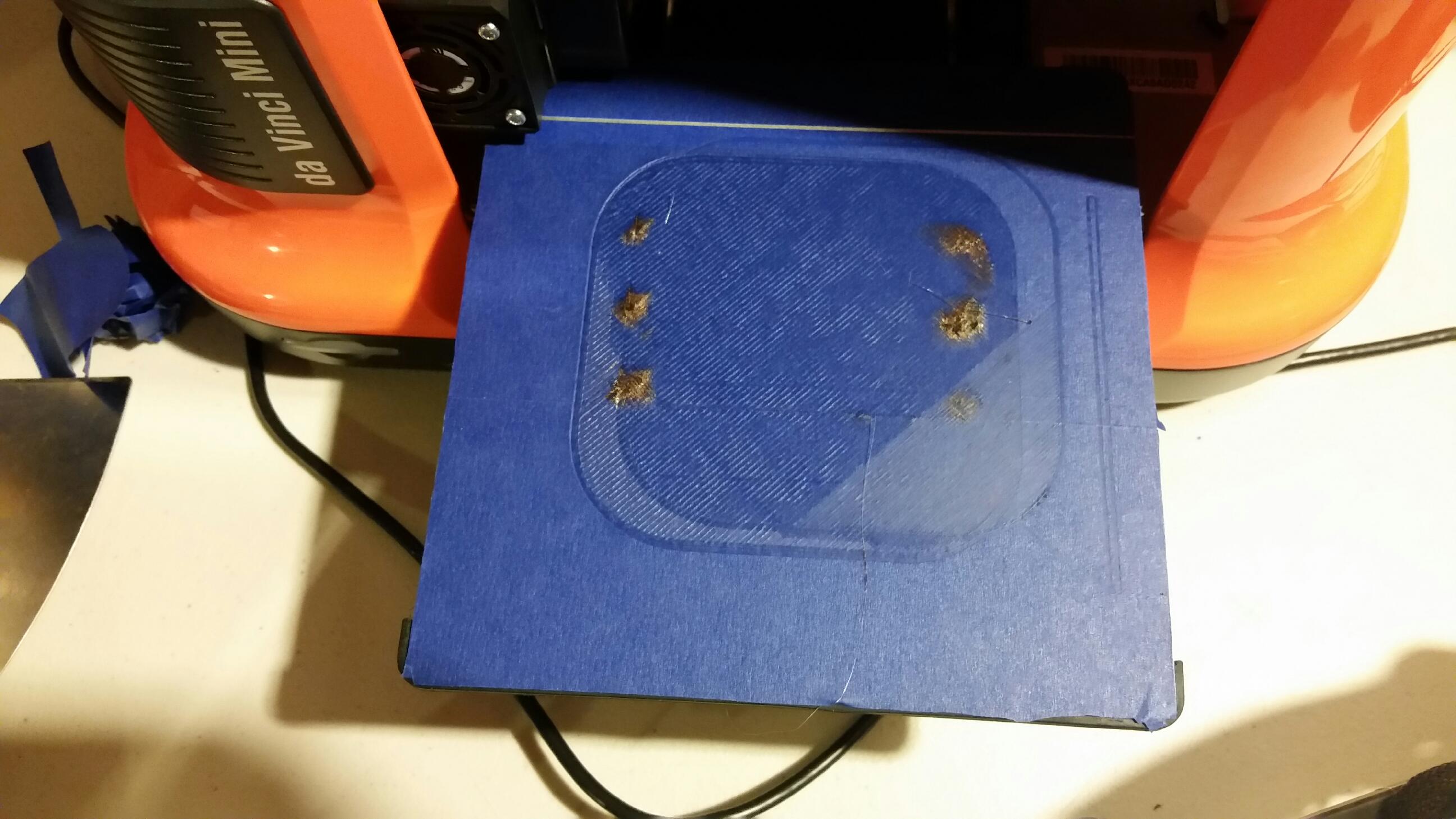

I have a Da Vinci Mini, which I am enjoying as my first printer so far. I have an issue with the screws (and 2 holes) on the bed. The 4 screws that hold then bed down stick up slightly above the surface of the bed, so any time that I print anything that has to go over those areas, there is always a large amount of build up that accumulates until it usually evens out a bunch of layers up finally. The last couple prints that I have been trying have apparently gotten caught on the little mountains that it forms and thrown off the rest of the print. I have certainly tried to level them with an allen key, but they are as tight as they're getting. Anyone else have this issue? I'm trying to think of ways to fix it and am thinking of cutting a piece of glass 6.5 x 6.5" and placing that on top, recalibrating with the glass in place so it knows it's there, then living happily ever after. Sound like a good idea, or are there better ideas? Thanks!

I'll post a pic of the issue shortly.