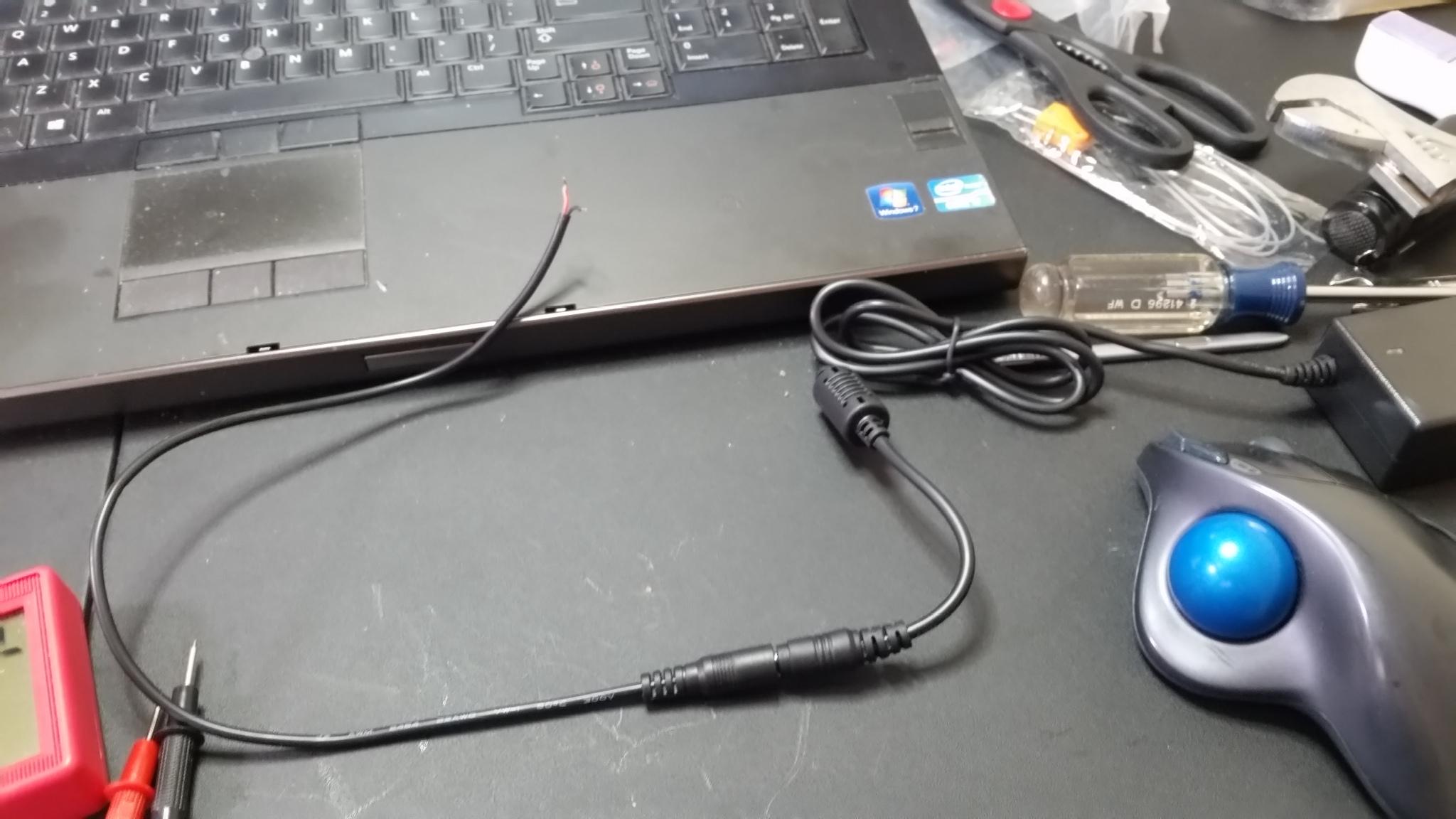

jwatt85 wrote:Also, I see the metal things (see picture) When and how do I use them, or if they have a specific name I can look them up.

They are call crimp ferrules. They are used to splice wires. When splicing, you can choose to solder, crimp using the ferrules, or use alternate connectors. heatshrink is not a solid bond to be used in place of a solder/crimp splicing, it is used to make sure the wires don't touch and short, so slide the heatshrink on before you make the splice.

The spade plug (little red guy) in your second pic will be used to connect to the motor. There are small pegs on your motor on which they will slide on.

I would assume the red is indeed positive, but you really should have a meter for instances like this. They only run about $20 at Home Depot

Printit Mason and Printit Horizon printers

Multiple SD2s- Bulldog XL, E3D v5/v6/Lite6, Volcano, Hobb Goblin, Titan, .9 motor, Lawsy carriages, direct Y drive, fishing line...the list goes on

Filawinder and Filastruder #1870.....worth every penny!