Topic: What have I done now?

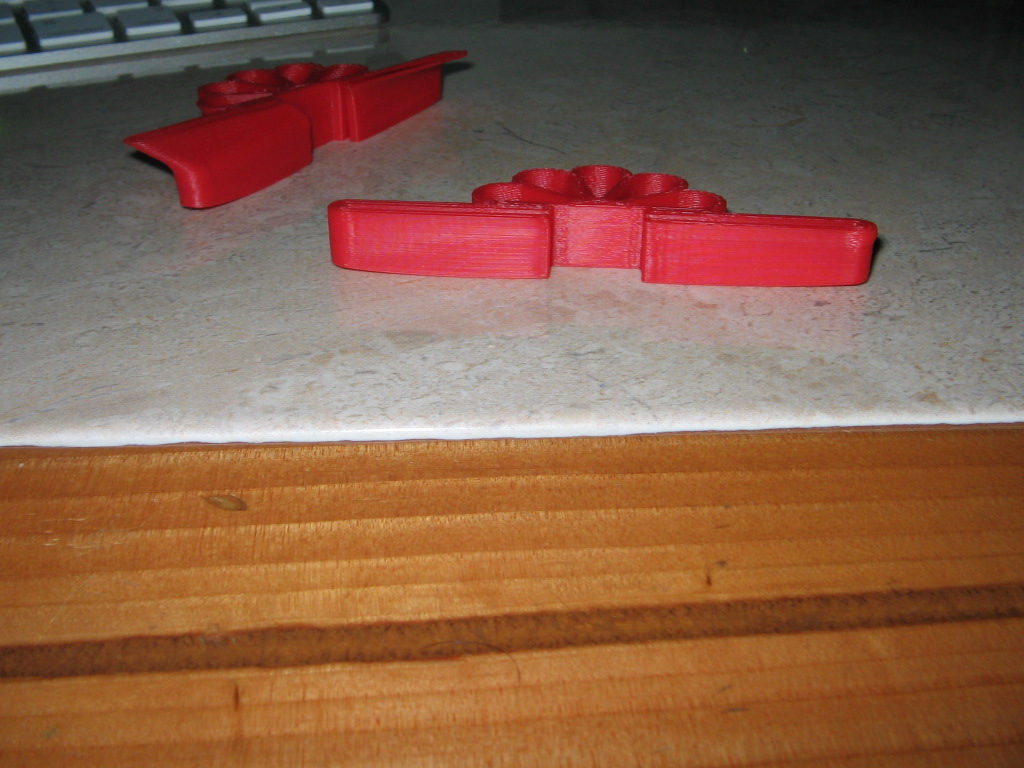

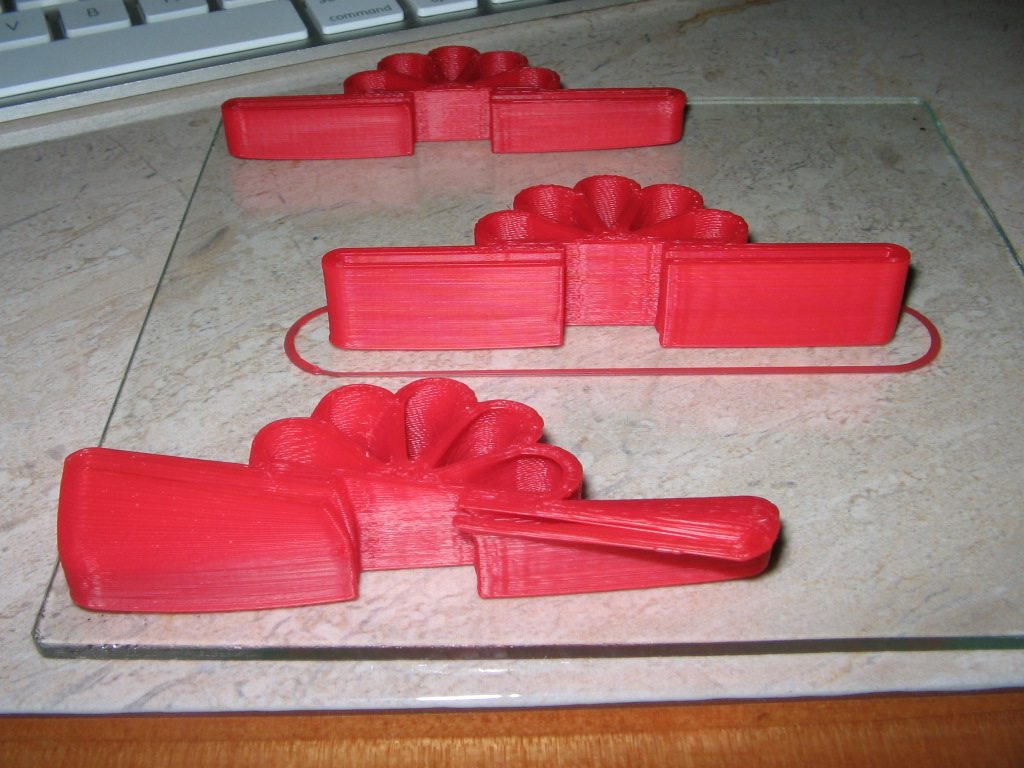

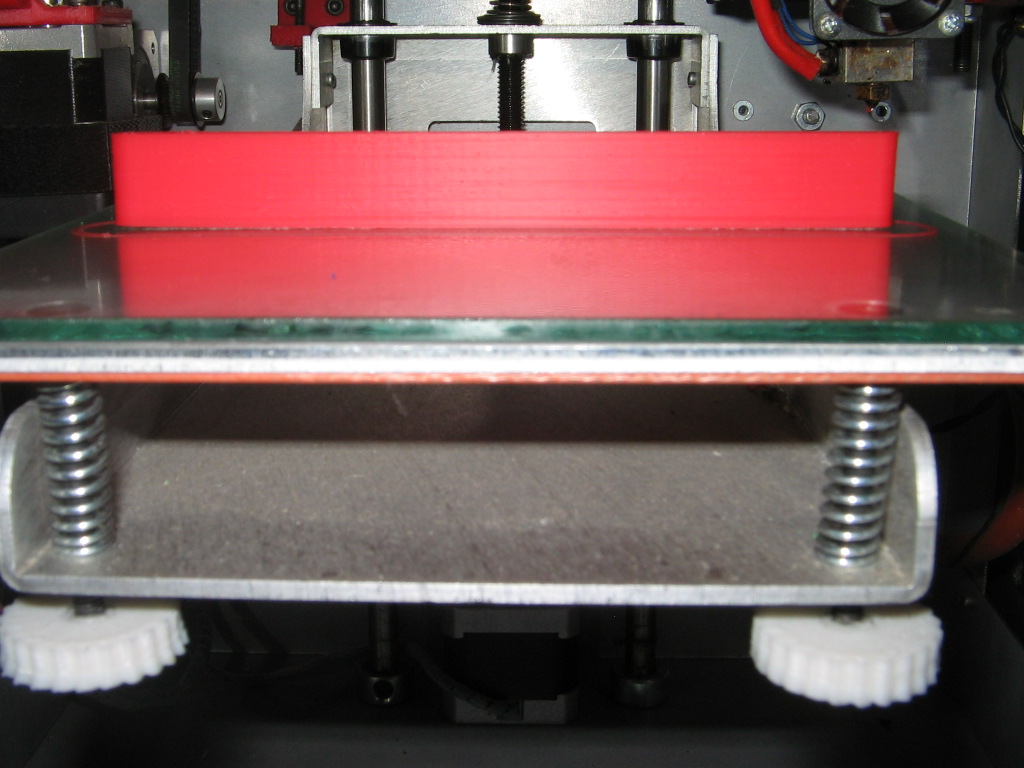

Haven't really turned on the printer for 6 - 7 months, honey-do list too long ( still come here 2 - 3 times a day). Tried today to print a few trinkets to adorn some Christmas packages. Months ago, I needed a razor blade and a small hammer to get the prints off the glass, both PLA & ABS - not now. They peel up like the first time I used the printer.

I did notice one thing, and that is most likely my problem. My Aqua Net is almost empty, that's Ok, but it it near 3 years old. When I pulled the failed print off, the small part that did stick brought most of the hair spray with it, in like a sheet - sticky too. Never heard of hair spray going sour, but never had a can for 3 years. Tomorrow I will re-check all calibrations, & re-level the deck - AFTER I get a new can of Aqua Net. Other than that, what could go wrong with the machine sitting untouched for a period of time?

Thanx for any help

Ski