the number of physical USB ports has nothing to do with the COM port number assigned - and you can change that number manually in Device Manager.

The driver needs to be installed before connecting the printer - if I recall correctly, it took me a few tries to get it to install correctly when we got our first Solidoodle.

1. Install driver - printer not connected.

2. Connect printer and power it up

3. Verify connection in Device manager -

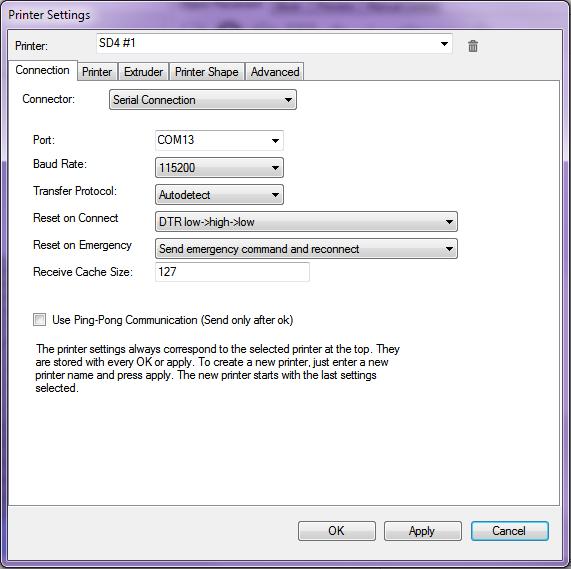

3a. Check Baud Rate settings in Device Manager - by default they are usually far too low - minimum setting is 115200, preferred is 250000

3b. I would recommend changing the COM port number to something above 10 before proceeding any further.

4. Start Repetier Host (side note: it usually works best to power up the printer before starting RH)

5. In RH, click on Config > Printer Settings to configure your connection - should look something like this

5a. Set the baud rate to match what you set in Device Manager, COM port as well. (Com port will only be available if the printer is powered up)

6. Click "Apply" and close that window.

you should now be able to connect to your printer.

Once connected, you should go to the manual control tab in RH, and try moving the different axis of the printer.

You may need to "home" the printer first (click on the little house icon) - be ready to click the emergency stop button, in case it doesn't want to stop - or moves in the wrong direction... "home" should be right rear.

If that happens, you will most likely need to do a bit more configuration to get things operating properly.

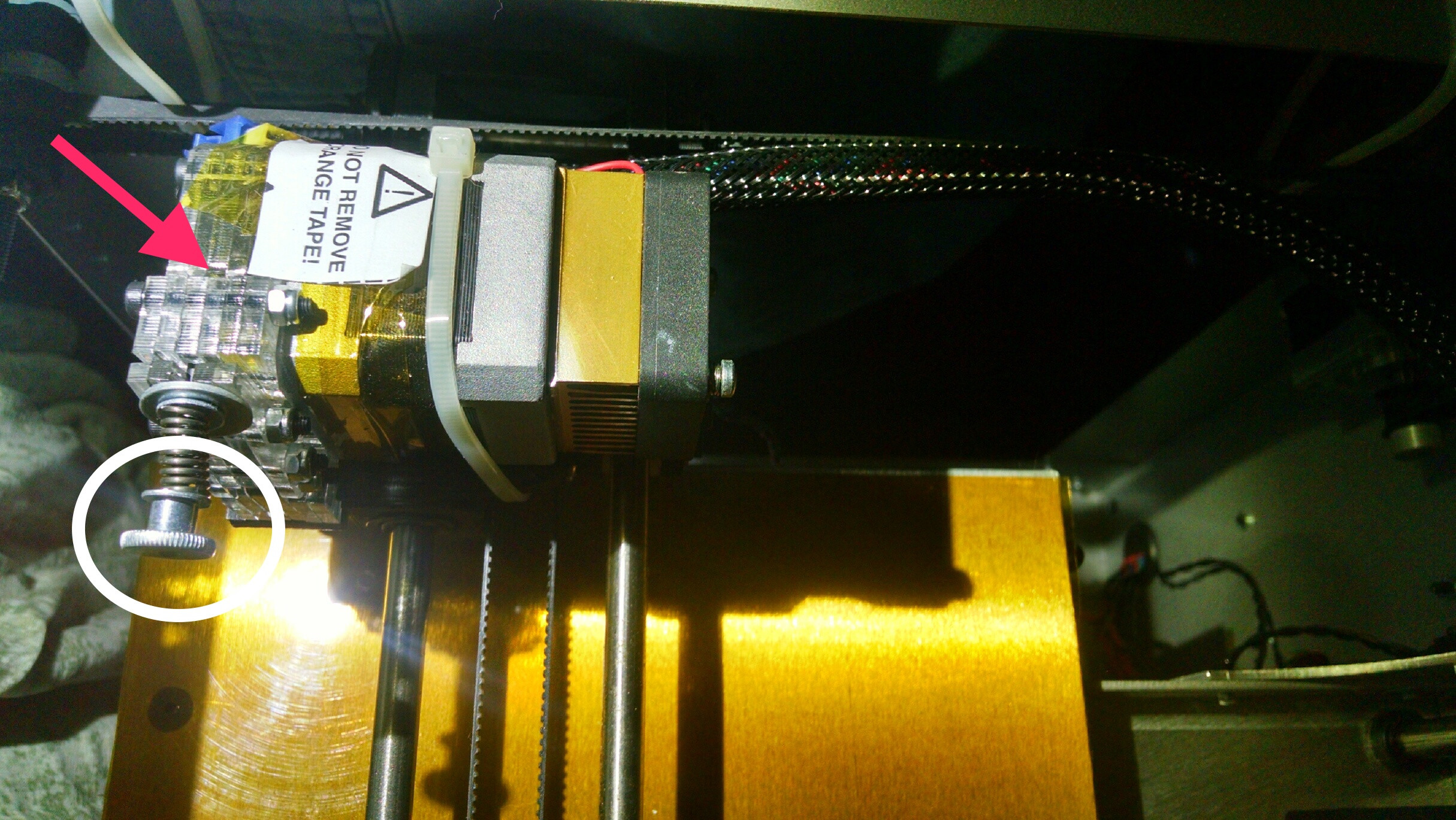

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1