There are many 3D scanners on the market to choose from. Some of them are open source, some of them are not.

Made by one of the most recognizable brands in 3D printing, the MakerBot Digitizer works with a laser and camera mechanism, together with a rotating platform. This 3D scanner can capture objects that are 8×8 inches big, and 2×2 inches small.

Other methods use 3D scanning software like Autodesk 123D Catch or a modified Microsoft Kinect. Because the Kinect is handheld, there are no theoretical limits to the size of the object you can 3D scan; rather, the constraints come from the person wielding the 3D scanner! The Fabscan Pi Project is another exciting option, where you can build your own 3D scanner using a Raspberry Pi.

Breaking the process down into smaller chunks, there are several things to know about how a typical 3D scanner works:

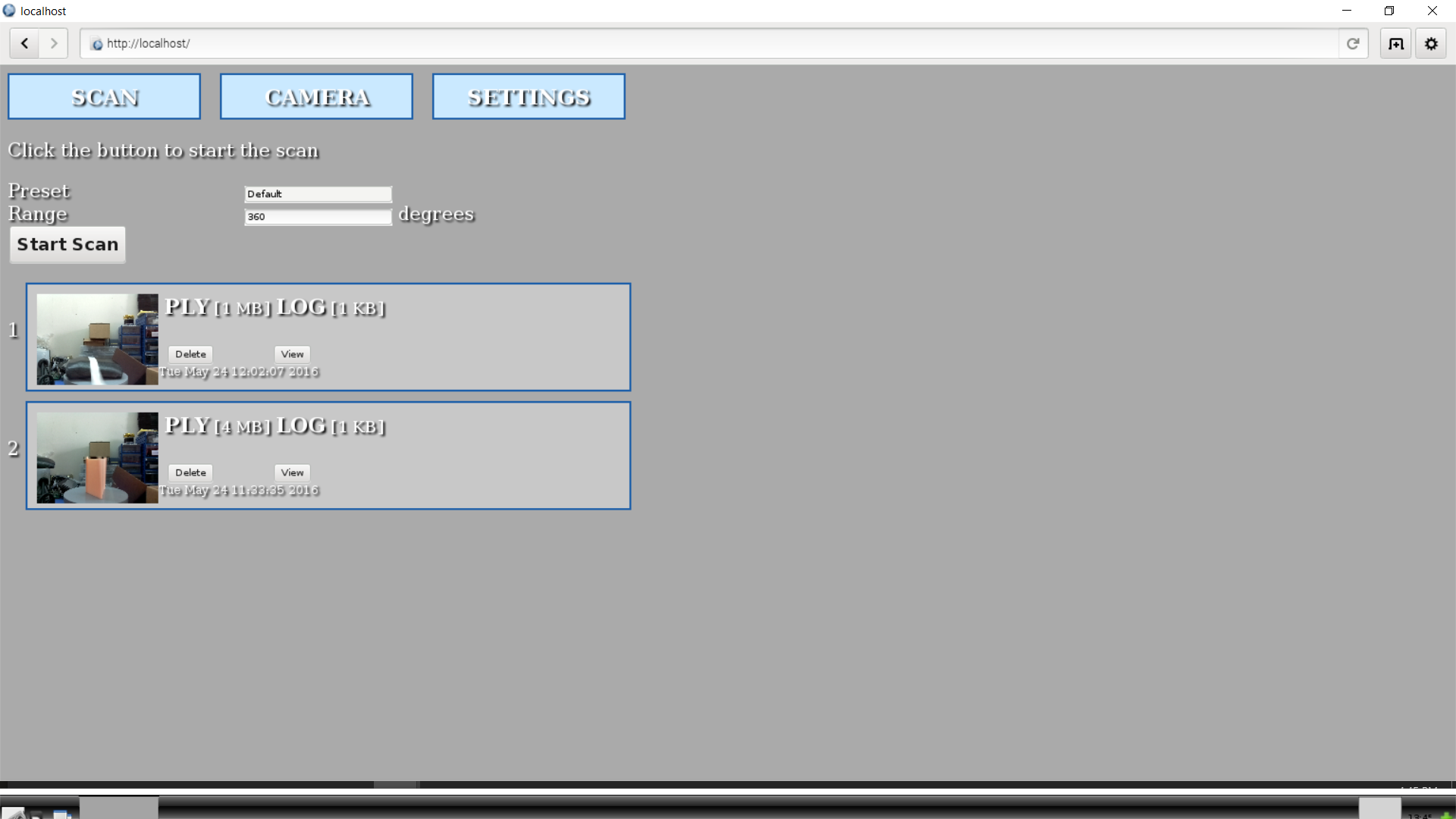

Laser & Camera: A laser line is projected onto the surface of an object. As the object rotates on the turntable, the camera picks up the laser line and processes it into data points, known as a point cloud.

Turntable: The turntable slowly spins the object so the camera can gradually capture every angle and contour.

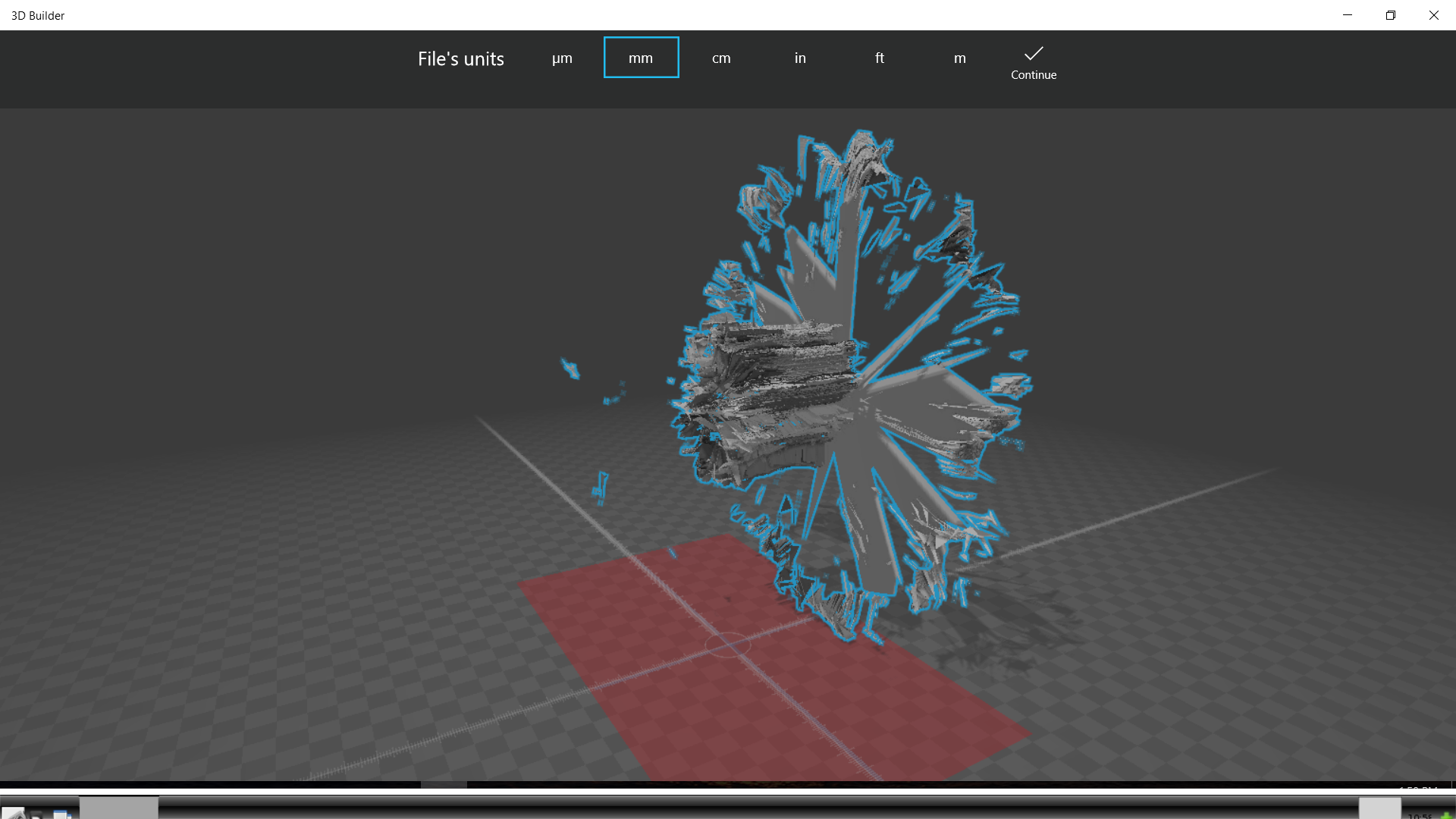

Point Cloud: Data points in space recreate the object’s surface digitally.

Mesh: The point cloud is then stitched together using software, to create a virtual representation of the source object with a complete, watertight mesh surface.

3d printing india

thanks

visit:http://vexmatech.com