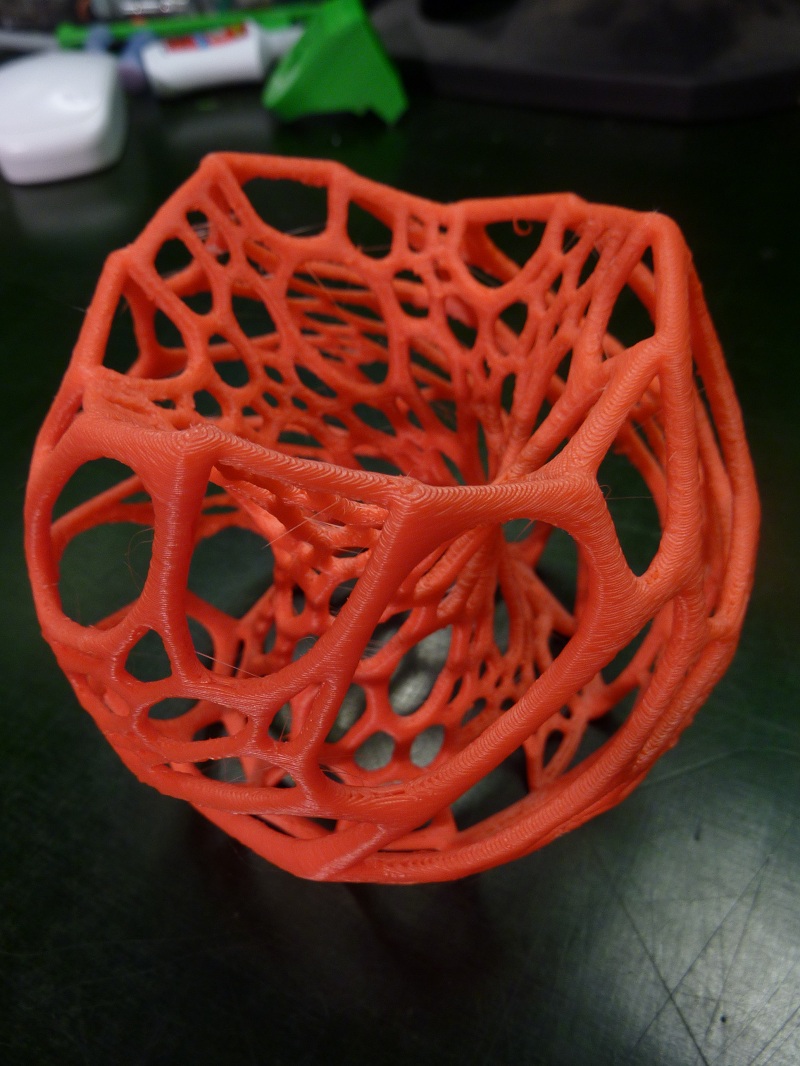

Topic: Cellular Lamp

http://www.thingiverse.com/thing:29365

Slic3r 0.9.2

; layer_height = 0.2

; perimeters = 3

; solid_layers = 4

; fill_density = 0

; perimeter_speed = 20

; infill_speed = 60

; travel_speed = 80

; scale = 1

; nozzle_diameter = 0.38

; filament_diameter = 1.66

; extrusion_multiplier = .91

; single wall width = 0.42mm

; first layer single wall width = 0.60mm

195C with a fan

Z Lift = .5 Keeps the nozzle from hitting curled up plastic and breaking the print

Retraction Distance = 1

Retraction Speed = 50

Bridging Speed = 70 Stretches the filament

Bridging Flow Rate = .8 Helps the stretching

Brim = 5mm

The brim helps it stick to the bed, since the footprint is a bit thin

The biggest problem I had was that overhanging perimeters would curl up as they cooled, and then the nozzle would hit them, eventually breaking pieces or skipping steps. I got a tip from the Rep Rap forum to increase the nozzle size a bit. Setting it to .38 causes the filaments to be spaced a little wider, but not wide enough to cause gaps. The idea is that they would be a little more prone to drooping, which would help counteract the curling up. I'm not sure if this really helped, or if it is all due to the Z lift.

I couldn't use Skeinforge for this, because SF wanted to make every layer solid, despite infill being 0. This meant a lot of plastic getting packed into tiny outlines, which caused a big problem with nozzle collisions. It's possible that reducing the flow would counter that, but that would take a lot of trial and error. I prefer to keep those settings where they belong, and control the density through infill and perimeters.

I had a fan blowing around the nozzle the whole time. I'll post the fan duct in another thread. It's not ready for Thingiverse because I want to tweak it so it can glue onto Neil's extruder mount without getting in the way of the long screws at the bottom of the extruder.

Now to be super picky-

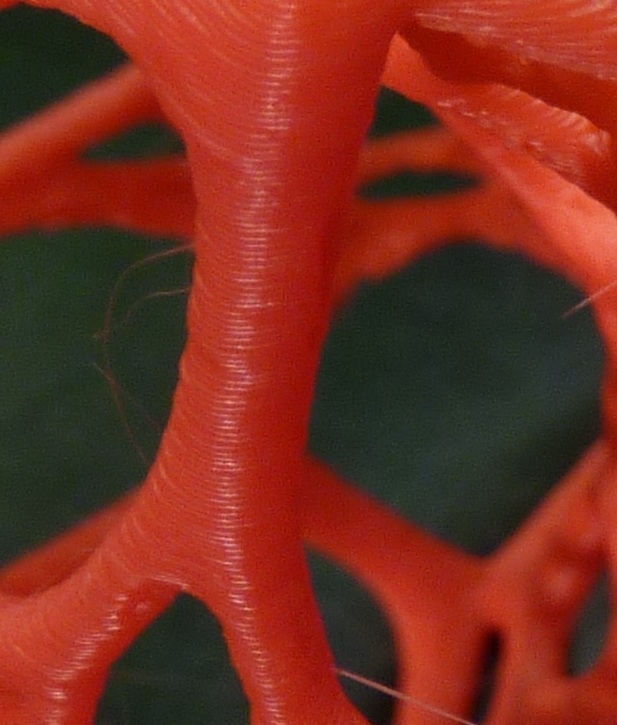

My Z wobble is evident in parts of the print. If you look at the slight variation in layers and imagine the threads of a screw, you can see it. John says they are sending me one of the new rods which are drilled out to mount directly on the motor, so hopefully it is coming and will make a difference in prints like this one.