Topic: This will sound nutty but (Filament Splicing)

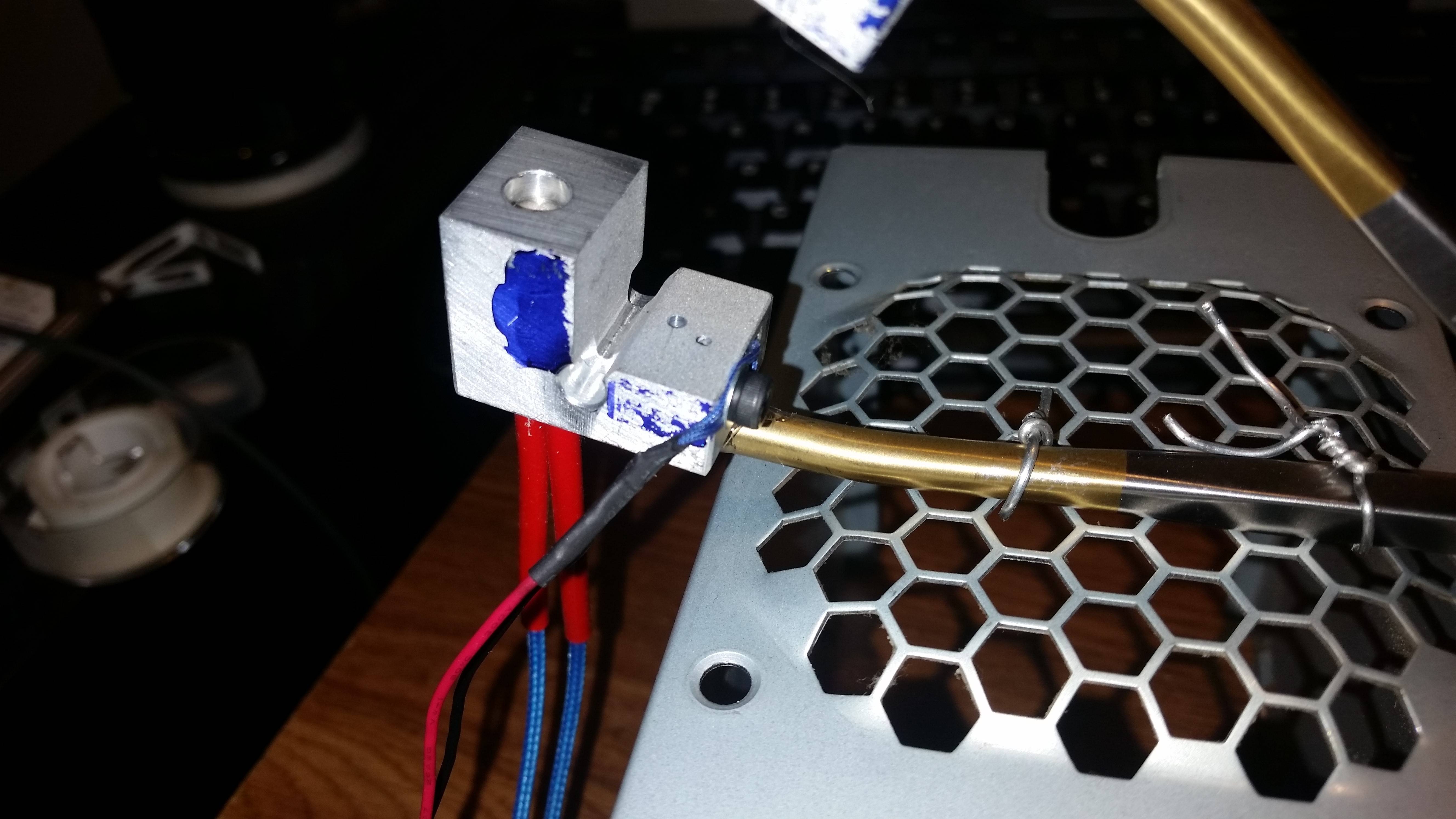

does anyone know of a way to glue or weld or otherwise connect pieces of filament, end-to-end?

I want to attach various types of one plastic type (like all ABS) maybe different colors, metallic, clear, etc. so the printed object is a composite, layers of aesthetically complimentary stuff.

Ideally, someone would make multi-material filaments maybe multi-color, multi-transparents/translucent and multi-metals.

I envision an object made of layers of aluminum, brass, iron, bronze, silver maybe interspersed with blacks and clear or maybe stone and wood.