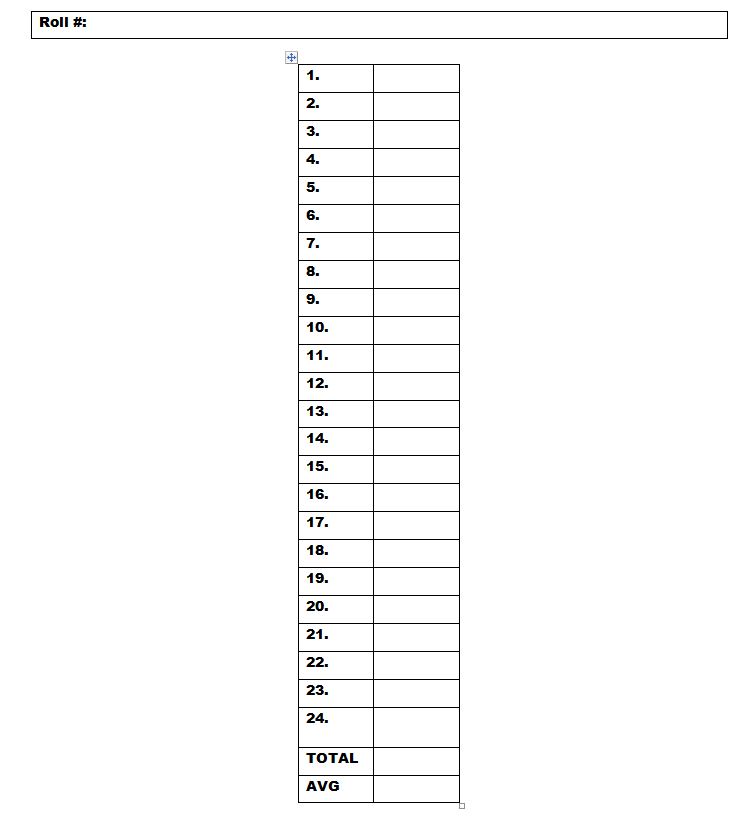

I set up a spreadsheet for doing my filament calibrations. Takes maybe 15 mins to do the whole routine.

Keeps everything in one spot, easy access, and does the math for you.

The attached copy was set up for "newbies" with a little extra info included. I have had several 'new to 3d printing' people ask me how to do these calibrations, which prompted me to make this spreadsheet available to them.

dubbsd - measuring every 3 inches seems a little bit of overkill, but hey, if it works for you...

Post's attachmentsFilament Calibration.xlsx 72.44 kb, 6 downloads since 2016-03-19

You don't have the permssions to download the attachments of this post.

SD4 #1 & #2 - Lawsy carriages, E3D v6, Rumba controller board, mirror bed plate, X motor fan, upgraded PSU & Mica bed heater

SD4 #3 - in the works ~ Folgertech FT-5, rev 1

Printit Industries Beta Tester - Horizon H1