Topic: My Filastruder and Results so far! (ABS and PLA)

I purchased the beta case and had my entire filastruder together in about 1.5 hours. Actually, my girlfriend had it together. This one is going to be hers and she is making me use the Beta one that I picked up from Tim in the Buy/sell/trade section. Either way, the only hiccup so far was reversing the order of the shaft collar and nylon bushing. I didn't catch that before she had the case together and found it only after running some plastic through. A quick shot with the torch help get the plastic hot enough pull out the auger and do a quick rearrange. It also let me double check the work to see that everything else got put together correctly.

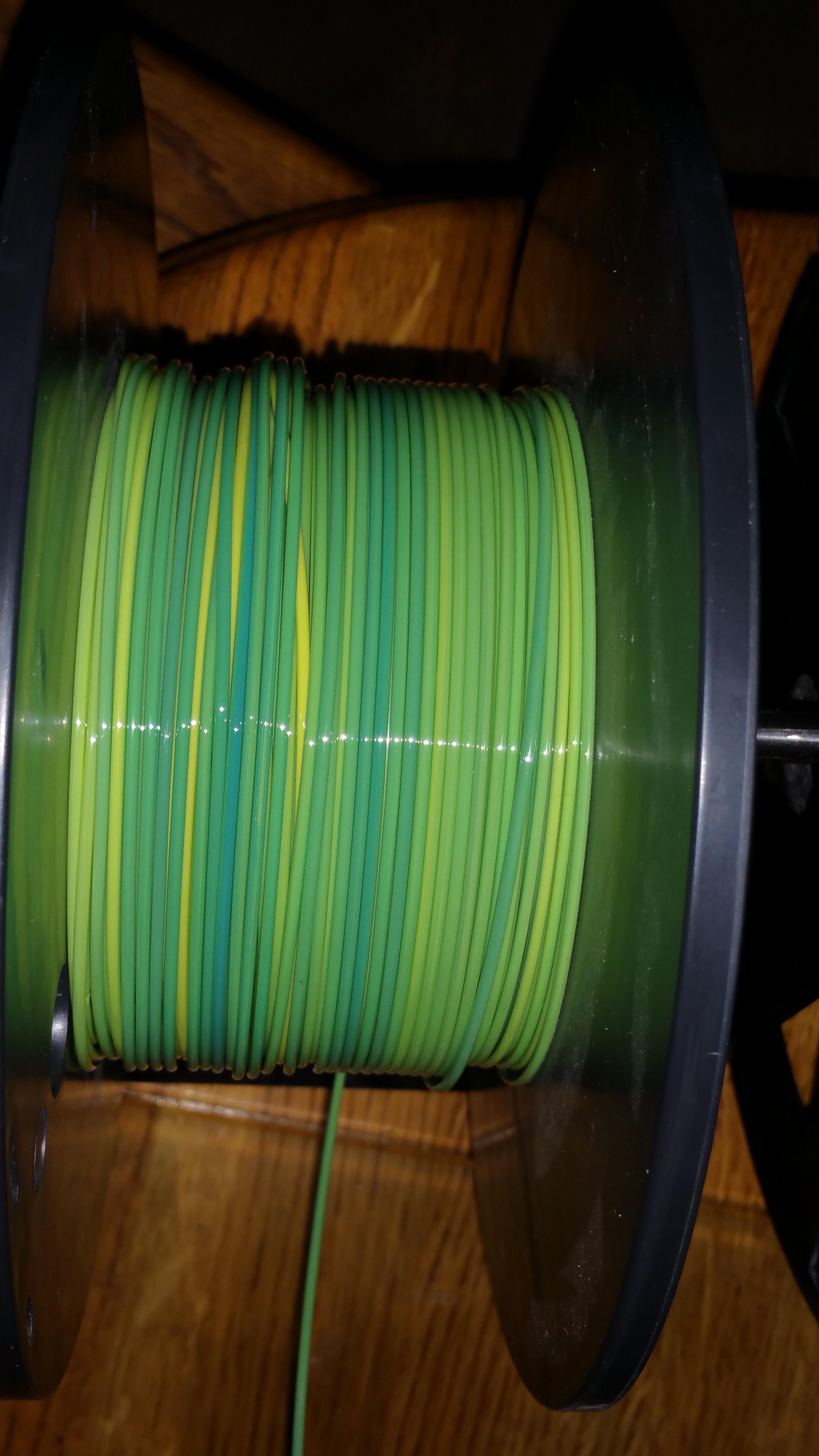

We have already run >5 lbs of ABS through this filastruder. The other filastruder is running PLA. I am using it currently to test how colorants mix depending on temperature. I found some interesting results at lower temps (138-142) where the colors just start to blend and make for some cool patterns. I think I am going to get a new temperature controller from Tim since this PID controller is less effective at controlling the temperature than the fan is. Here are some results photos for the PLA.

It was pointed out that I forgot to attribute the artist:

Treefrog from thingiverse designed by MorenaP http://www.thingiverse.com/thing:18479

Glass bed with QU-BD heat pad upgrade, threadless ballscrew w/ 8mm smooth rod, spectra line belt replacement, lawsy MK5 extruder, Lawsy replacement carriage, E3D hotend, Ramps 1.4 w/ reprap discount controller, DRV8825 drivers, 12v 30A PS, Acrylic case, Overkill Y-idlers, Filament alarm, Extruder fan + more.